skyhighZJ

Thanks for your taxes

- Joined

- May 31, 2012

- Location

- Aberdeen, NC.

Those rims look great, Simple but a touch of class!

Hmmmmm I spend $140 and am done in 2 minutes.... should I smoke a cigarette.... I'm pretty sure that's illegal most states..... Damn I need I nap!

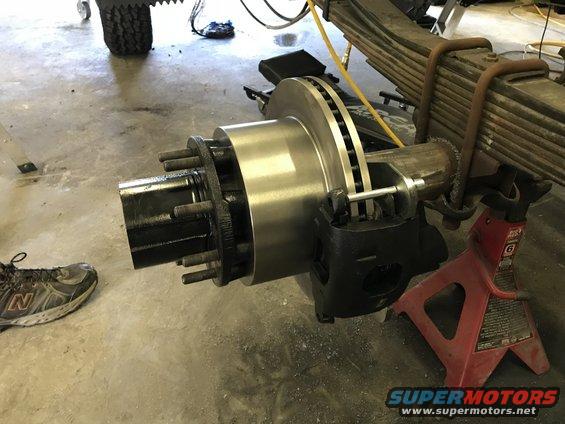

Oh and does anyone have a 14 bolt socket I can borrow???

You could have picked up an AAM 10.5 or 11.5 and had disc brakes and a parking brake. Just a thought....

View attachment 269649 Saw this RC Crawler on IG and thought of this build!

View attachment 269649 Saw this RC Crawler on IG and thought of this build!