Buffy

Well-Known Member

- Joined

- Jan 31, 2010

- Location

- Burlington, NC

Last summer I was cruising Crackslist and came across an interesting truck. I was tempted to buy it but was abled to resist it..... at first. The price kept coming down and it kept popping up in my searches screaming buy me. Well I bought it and this is going to be my build thread.

Here is said truck:

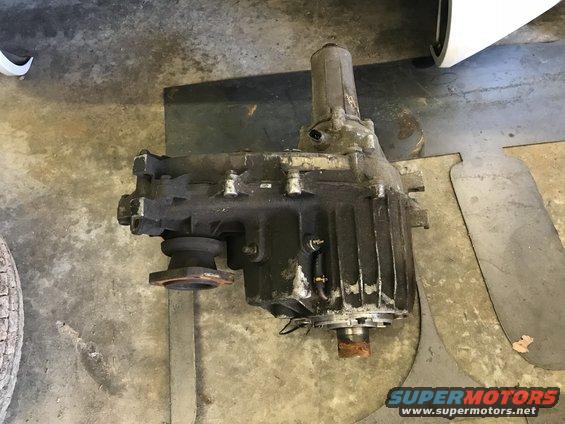

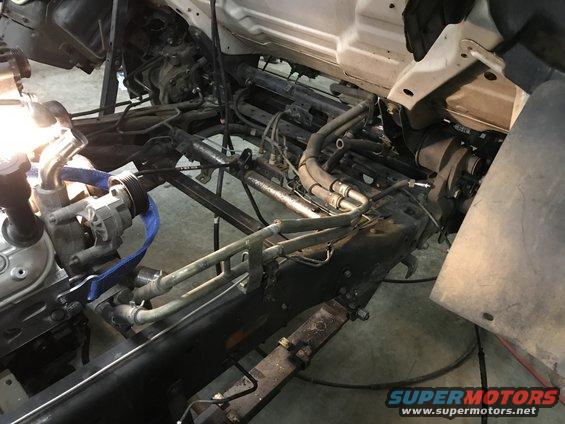

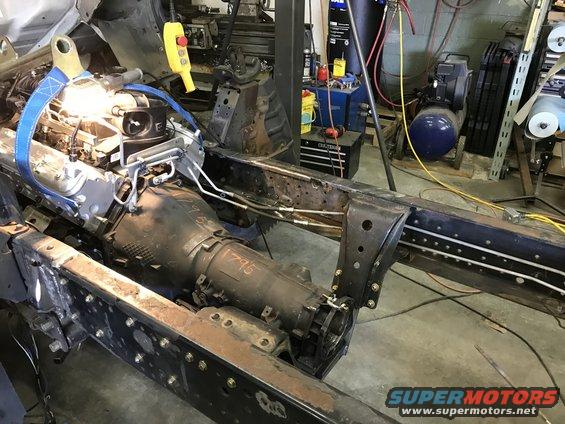

It was originally a diesel truck but the previous owner had put a Chevy 6.0 and 4L80 trans in it. So I went out and got me a 6.0 had it refreshed with a new cam, shaved the heads, etc... So this is what will be motivating my truck:

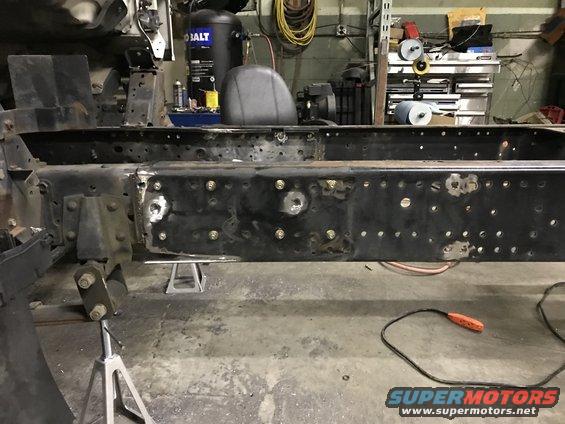

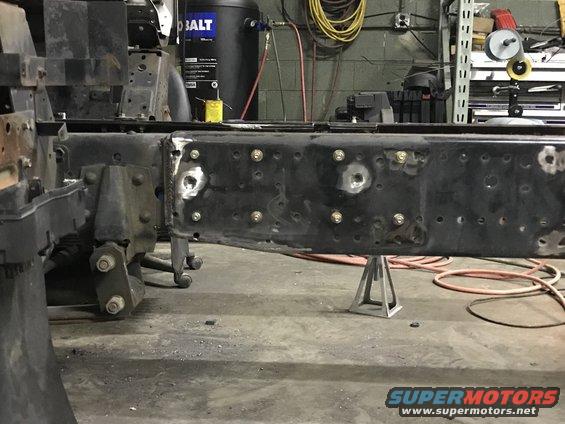

My original plan was to drop in the motor and have fun. But when we took the bed off we realized just how bad the frame work was not to mention the wheel base was only 79". That seemed a bit sketchy so plans were made to stretch the frame.

Here is said truck:

It was originally a diesel truck but the previous owner had put a Chevy 6.0 and 4L80 trans in it. So I went out and got me a 6.0 had it refreshed with a new cam, shaved the heads, etc... So this is what will be motivating my truck:

My original plan was to drop in the motor and have fun. But when we took the bed off we realized just how bad the frame work was not to mention the wheel base was only 79". That seemed a bit sketchy so plans were made to stretch the frame.