Pennsylvaniaboy

Well-Known Member

- Joined

- Jan 21, 2009

- Location

- Chambersburg, PA

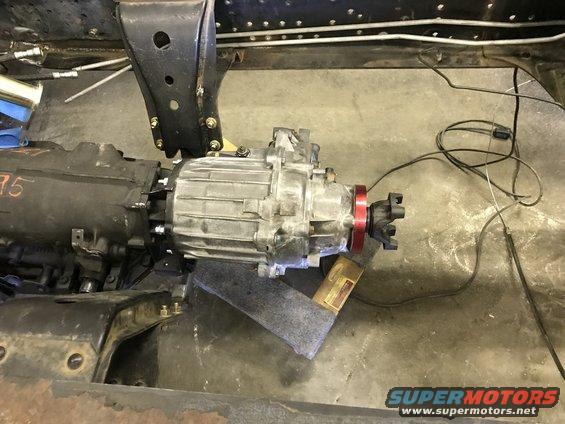

This is super cool. are you reusing the front springs? is there enough room for the pinion etc, or did you have to lift it some? Could you have redrill the perches?

And what the rear axle stock 8 lug or had someone swapped it?

And what the rear axle stock 8 lug or had someone swapped it?