My Steering Setup Parts List and Info

Here is what I have in my Steering and Track Bar.

Parts:

I begin by measuring between the tie rod mounts on the knuckles, This will help when you get ready to cut the DOM for the tie rod. I measured from center of the hole in the knuckle to center of the other hole. Then I removed the factory steering set up, A tie rod end puller helps a ton. Next cut the factory Sway Bar and Steering Stabilizer mounts off the axle. I also trimmed the spring perches as close the spring as possible. Then I drilled the knuckles out to 5/8, I got a 5/8 bit from the industrial supply house a good bit and strong drill makes it easier.

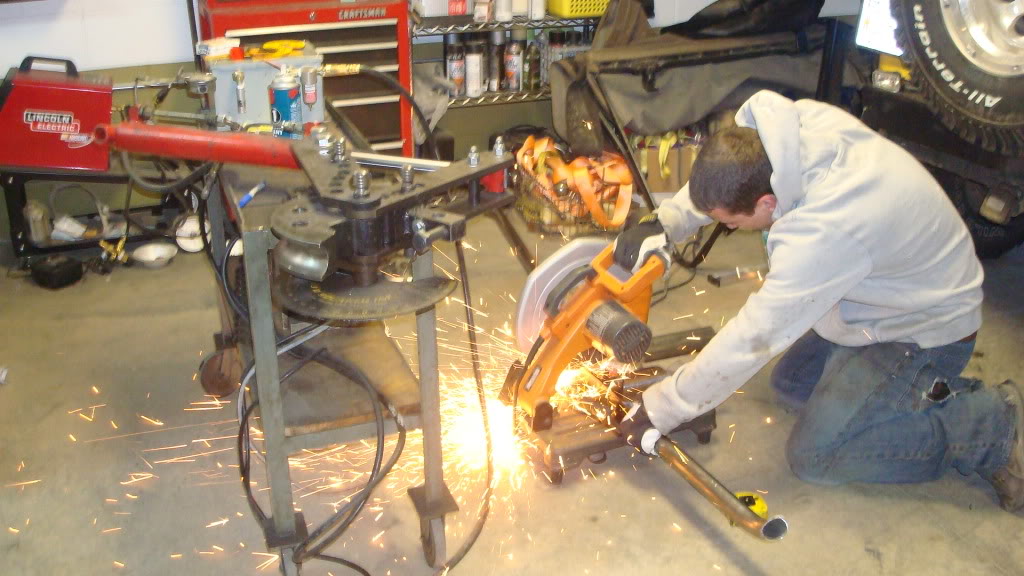

Now you can start mocking up the tie rods, I took my heim and threaded into the bung so that half of the threads are engaged and inserted it in the 10 foot stick of DOM, That way you can measure from center of the bore in the heim to the edge of the DOM. Take that measurement and multiply by two. Now take that measurement and substract it from the measurement you got from the stock tie rod. This will tell you how long the DOM for the tie rod needs to be. Cut it and take it together. I went ahead and mount it to the knuckles using the step down spacers.

Then drilled out the pit man arm, And the Multi-Purpose Tabs to 5/8s. Next I mounted the heims to the pitman arm (Still mount on the jeep) using the High Misalignment spacers and multi-purpose tabs using the step down spacers be sure to have the bungs threaded on to half the thread is showing. I set the tabs on top of the Tie Rod with the tips at the end of the DOM, The bolted heim holds the tabs together allowing it to sit on top of the tie rod. Now measure between the Bung Flange (Edge of the bung that touches the DOM) on the pitman arm and the Bung Flange on one at tabs to get the measurement of the Drag Link.

I used a scrap piece of 3/16 to box in the top of the tabs to make it stronger. I made some bushings for my steering out of scrap shock bushings for the front of the TJ the top side. I felt the steering to have a little play in it from the roll of the heims. We built the steering for "Wrangler00" with out the bushings and it feels the same so not sure there needed. I mounted my Tie Rod under the knuckle due to the size of my DOM, 1.5 DOM would fit on top to allow for better clearance.

Use a plum on a string to get the center of the jeep and mark it on the axle, remove the Track bar, the jeep will shift to the side, use a ratchet strap to pull it back to center. You will need to drill out the Track Bar mount on the Jeep and the one from Ruff Stuff its sent with 9/16s holes in it. I mounted the heim in the track bar mounts, same way as the drag link so you can measure. Place the track bar axle mount on the axle as close to the spring perch as possible. Then you can get the measurement for the track bar DOM. Mock it up and tack it together. I rotated the axle mount to get the angle as close to the drag link as possible. Then tack it to the axle.

Finally if all looks good burn all the welds in adding the gusset to the track bar mount.

I have had good luck with this set up. But I am no pro fab shop so be sure you do it so that it is safe. If your not a welder have someone weld it at a shop, I did.