DanStew

Well-Known Member

- Joined

- Jul 6, 2007

- Location

- Lexington/Columbia South Carolina

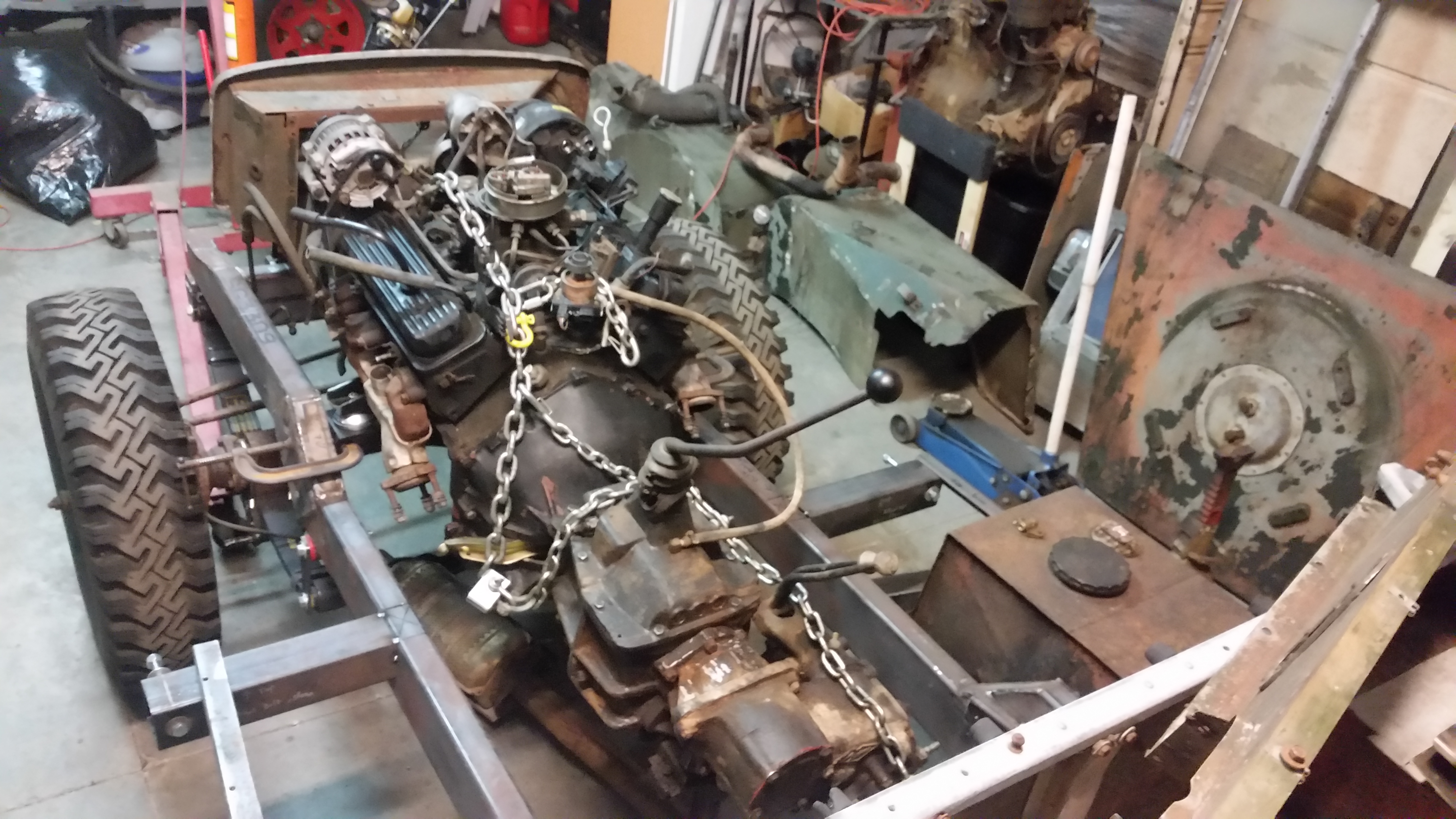

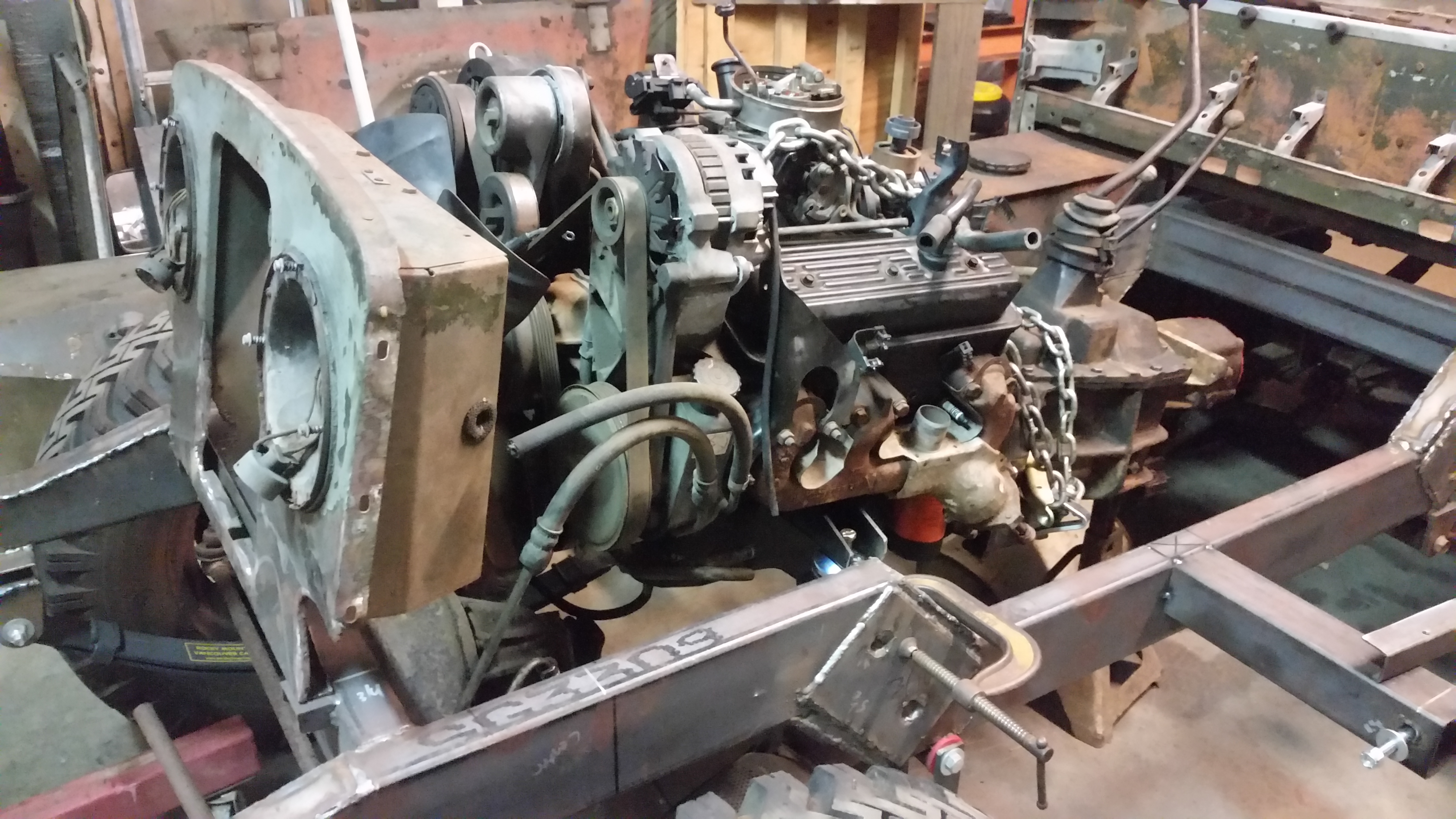

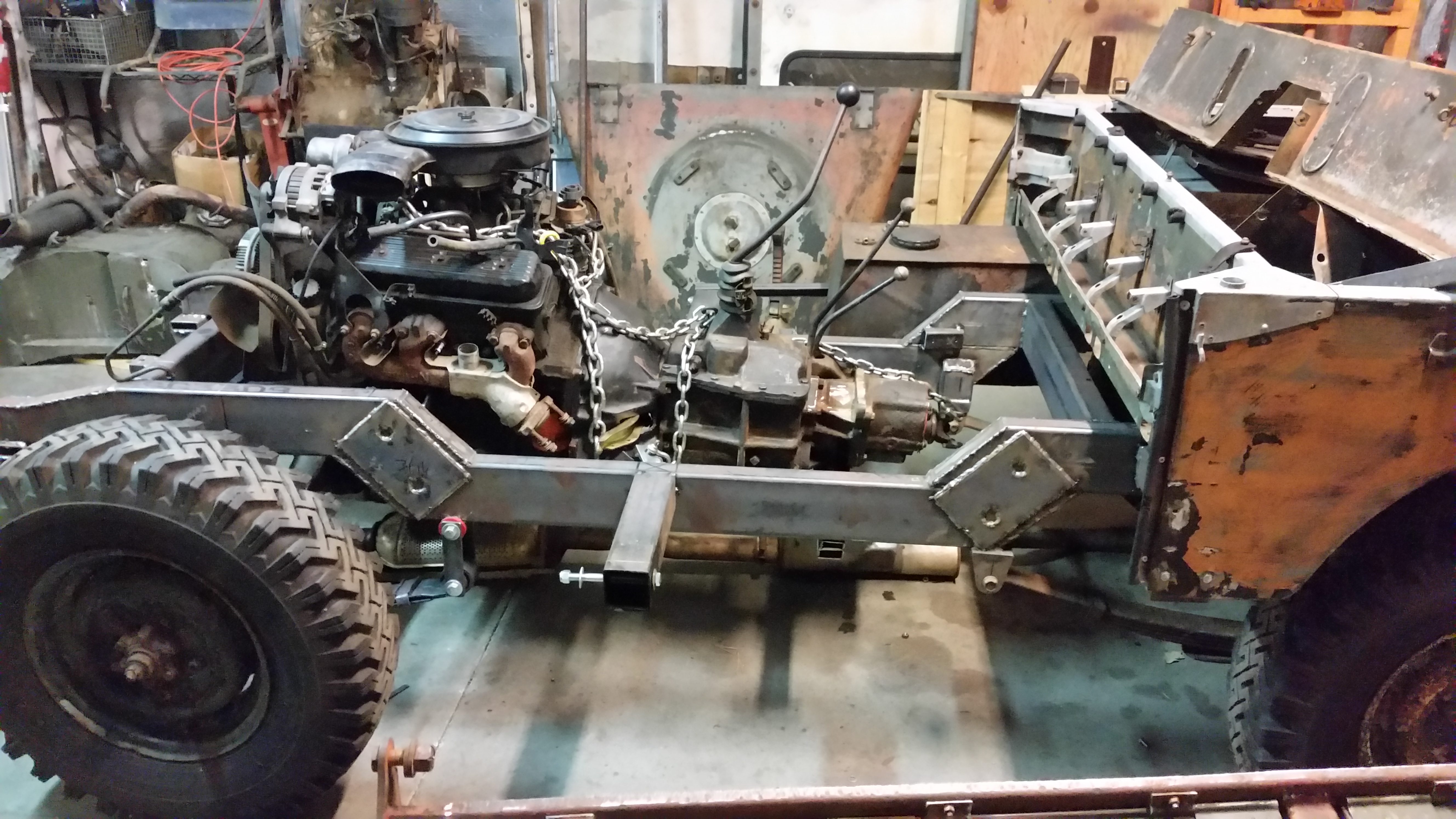

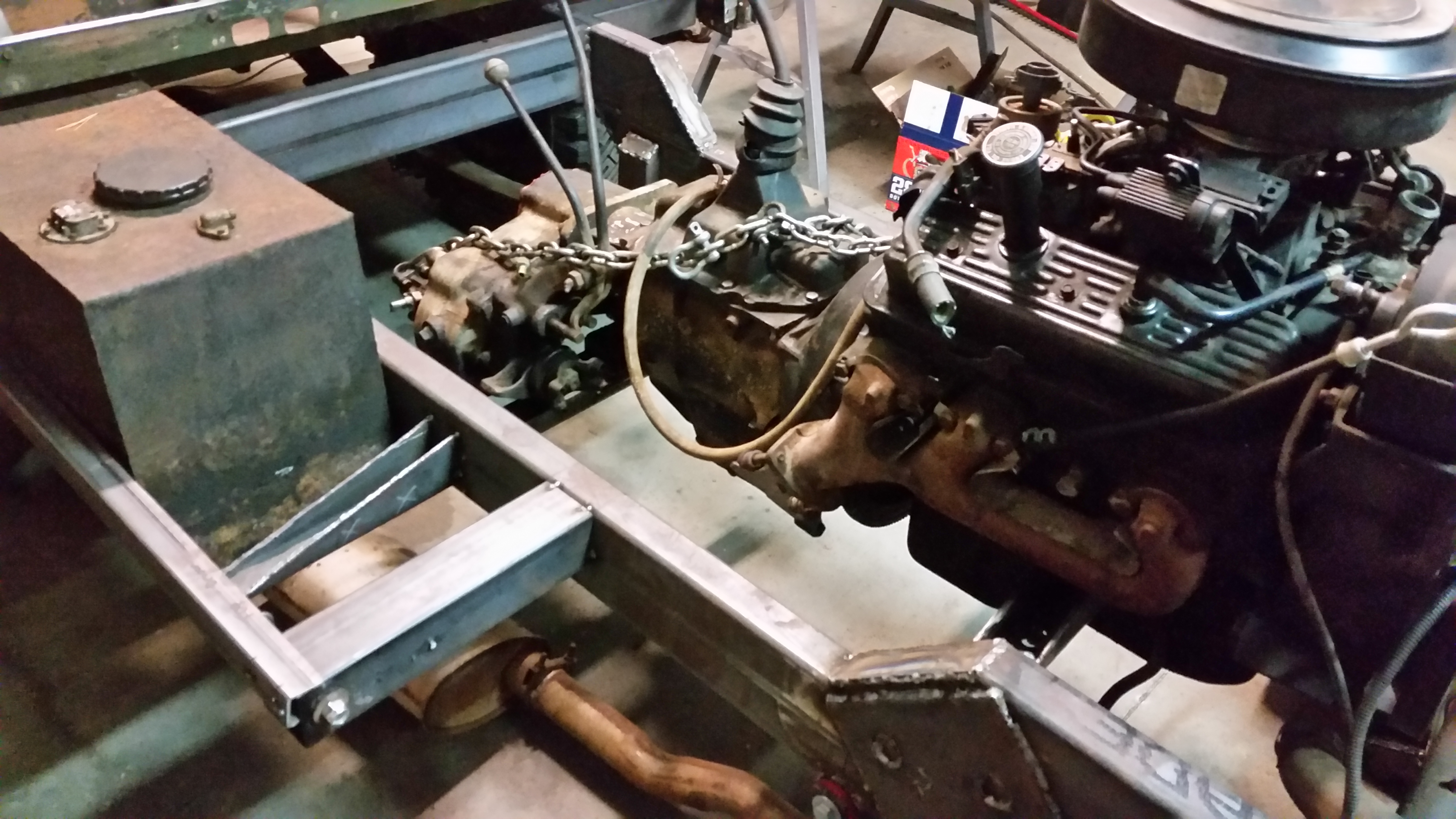

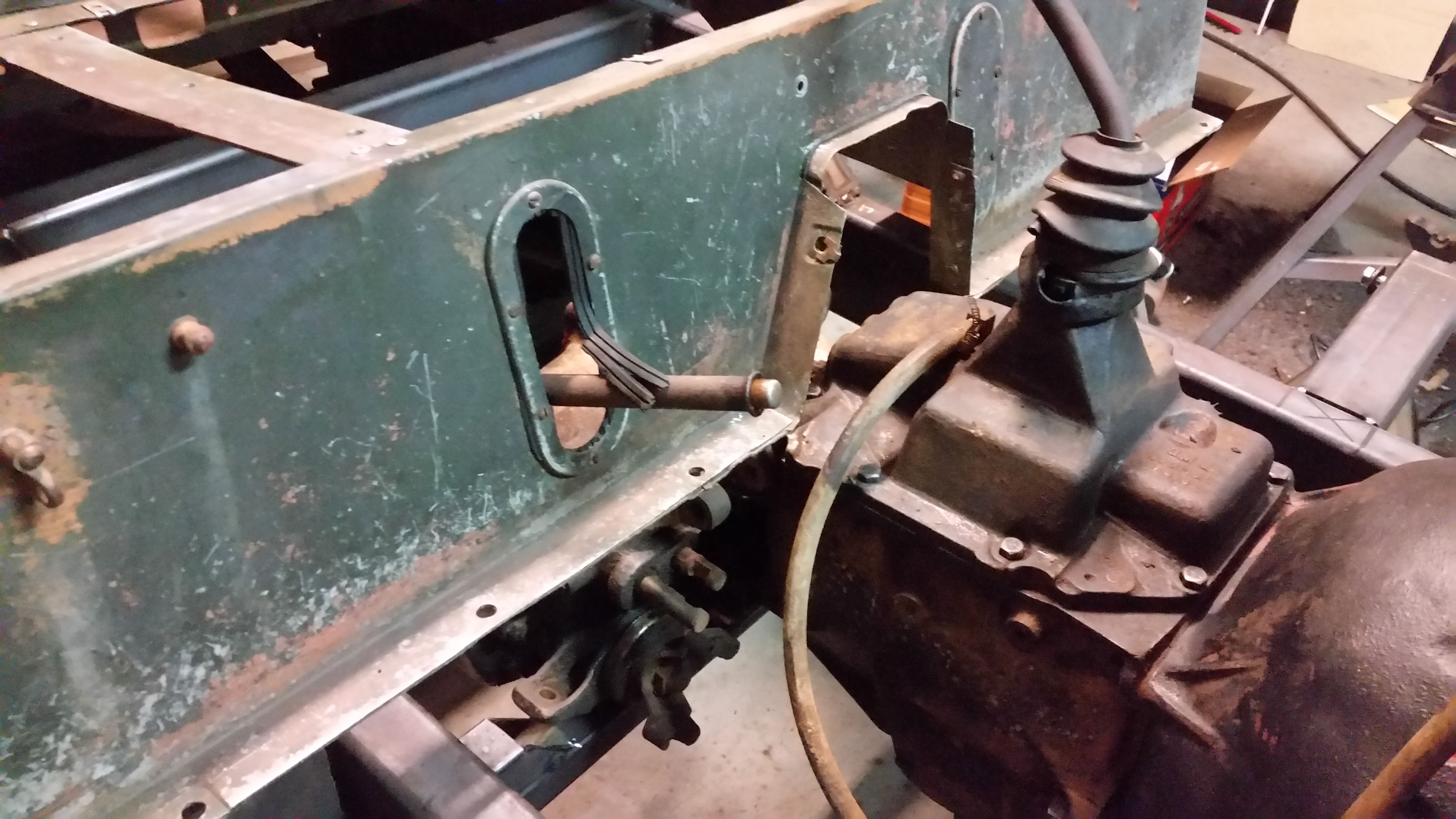

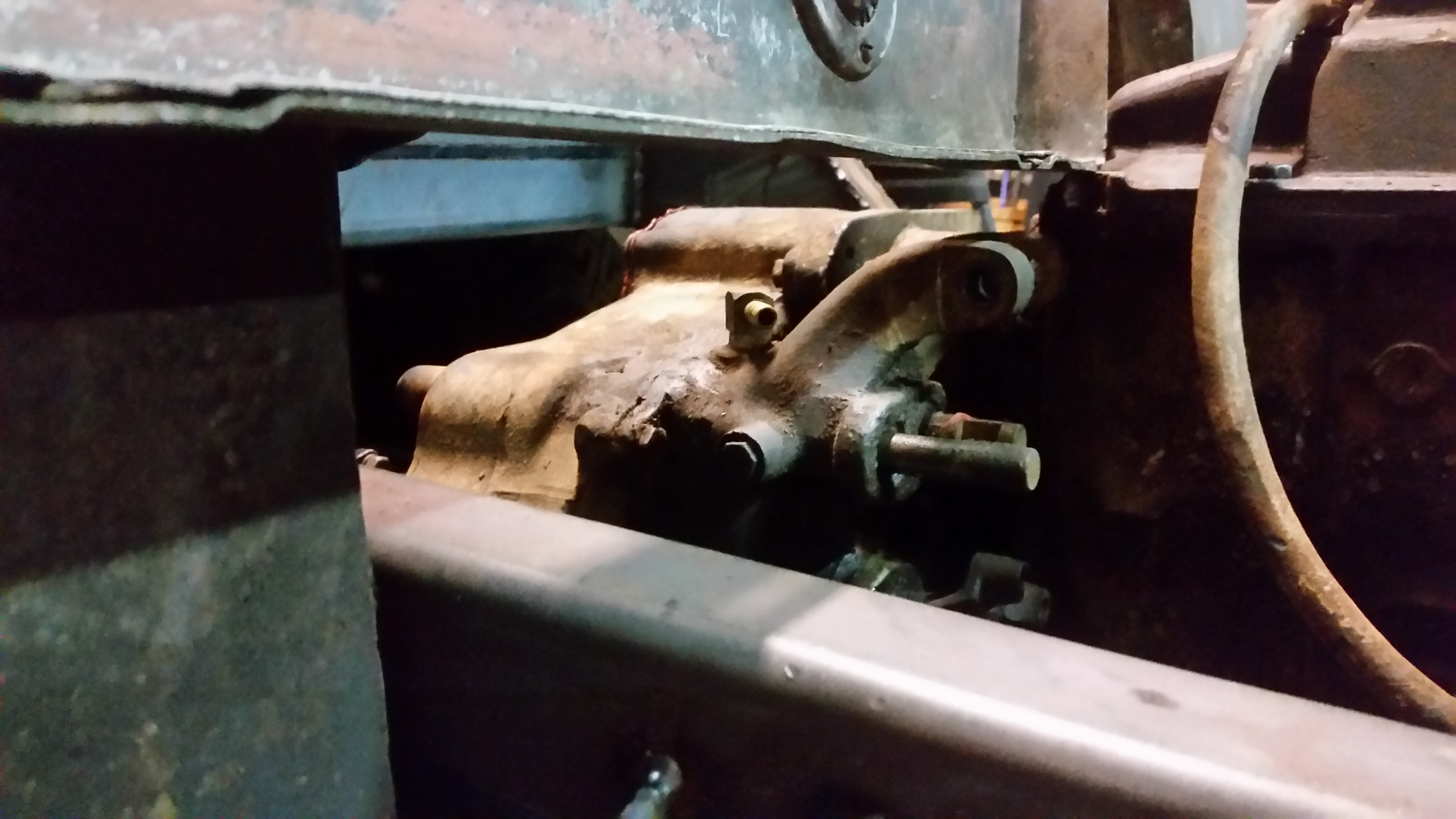

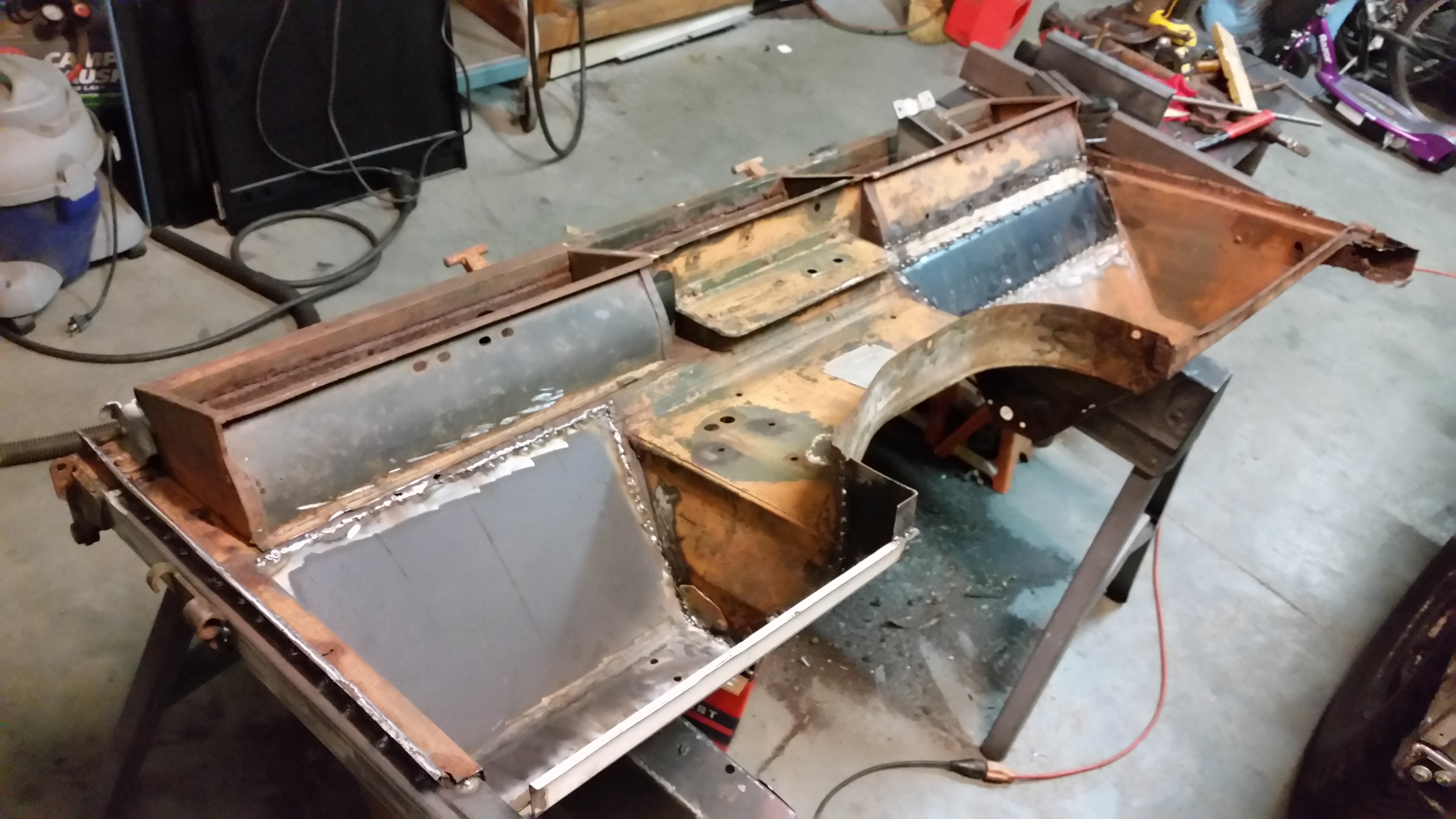

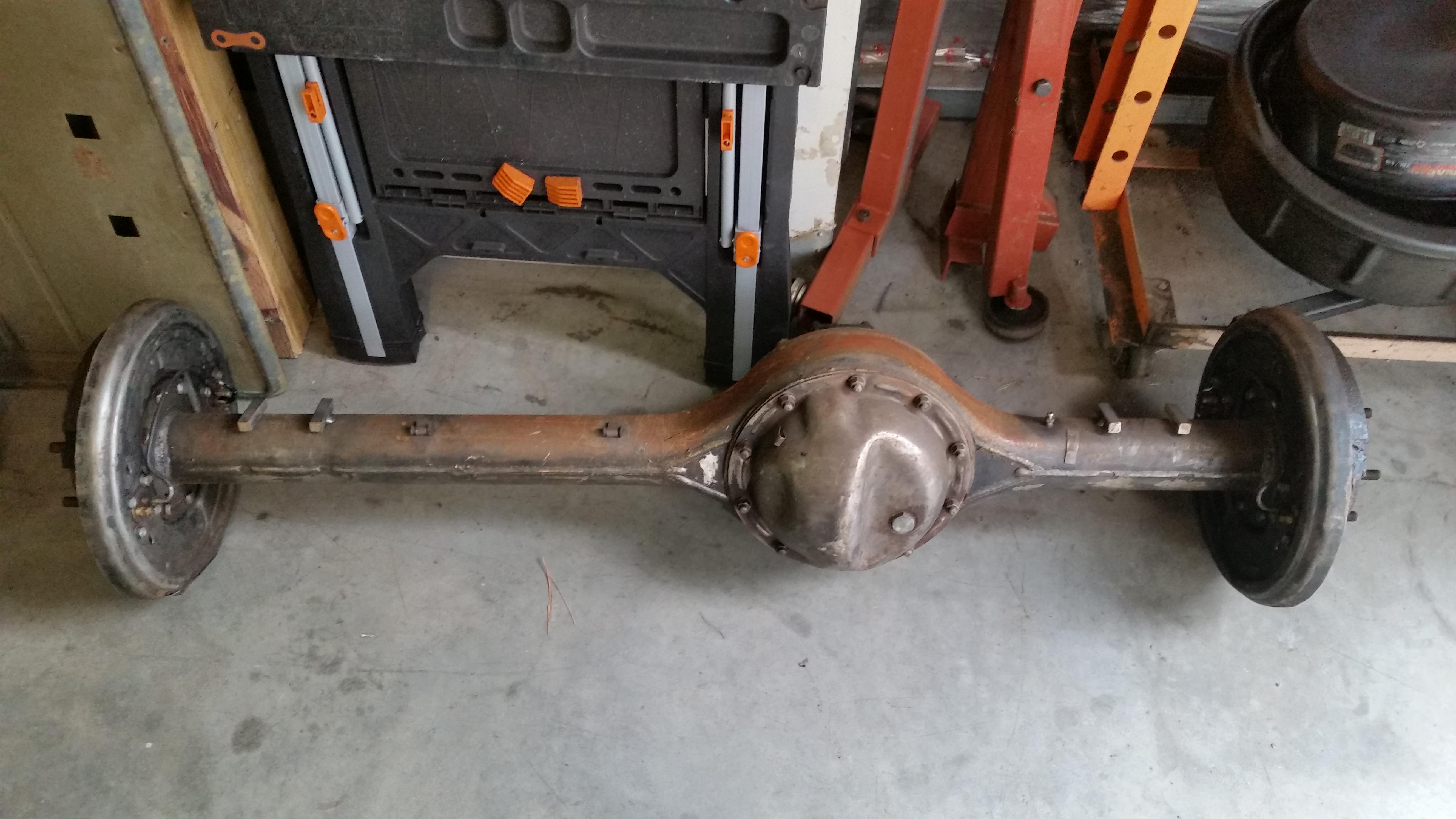

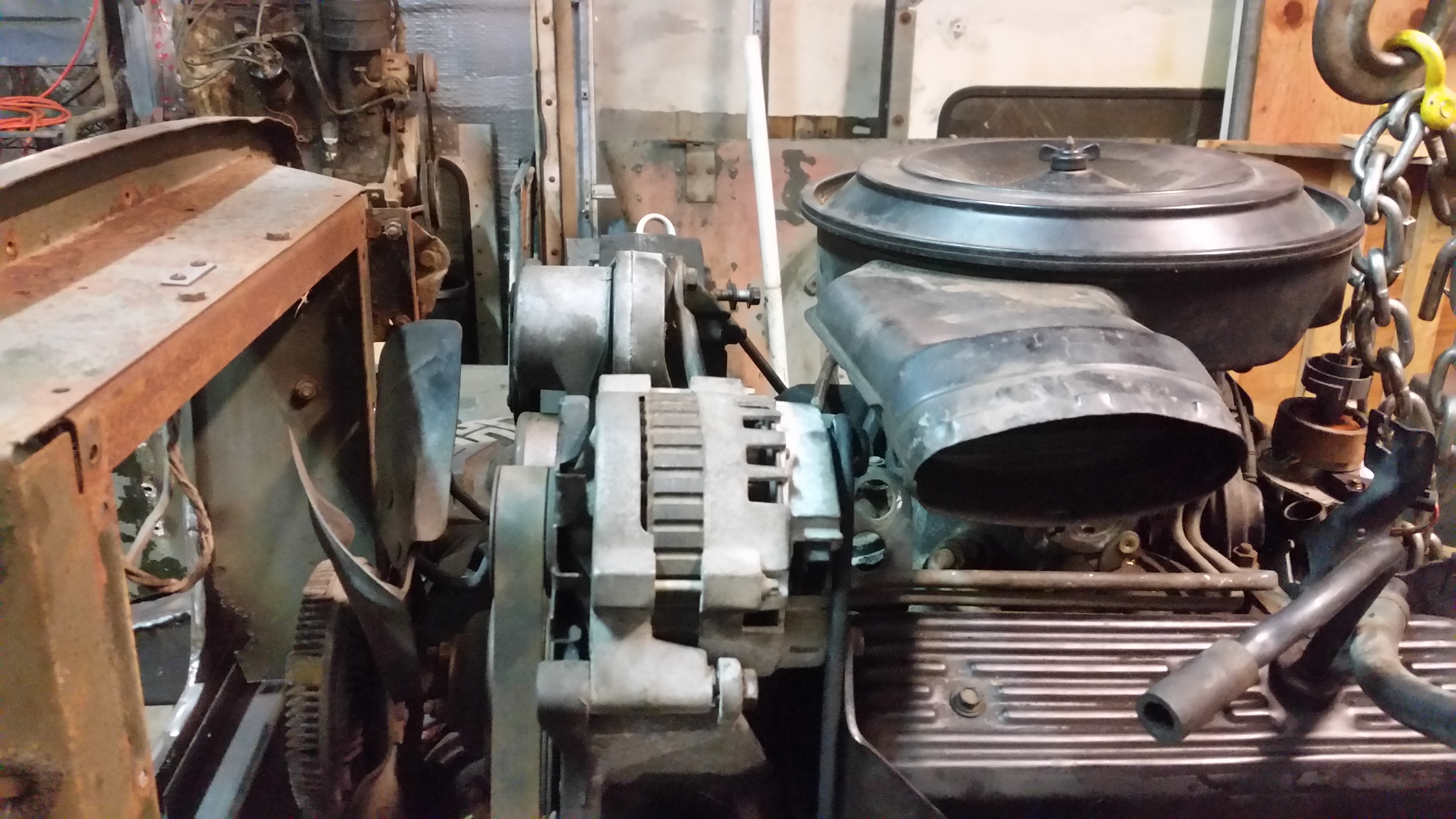

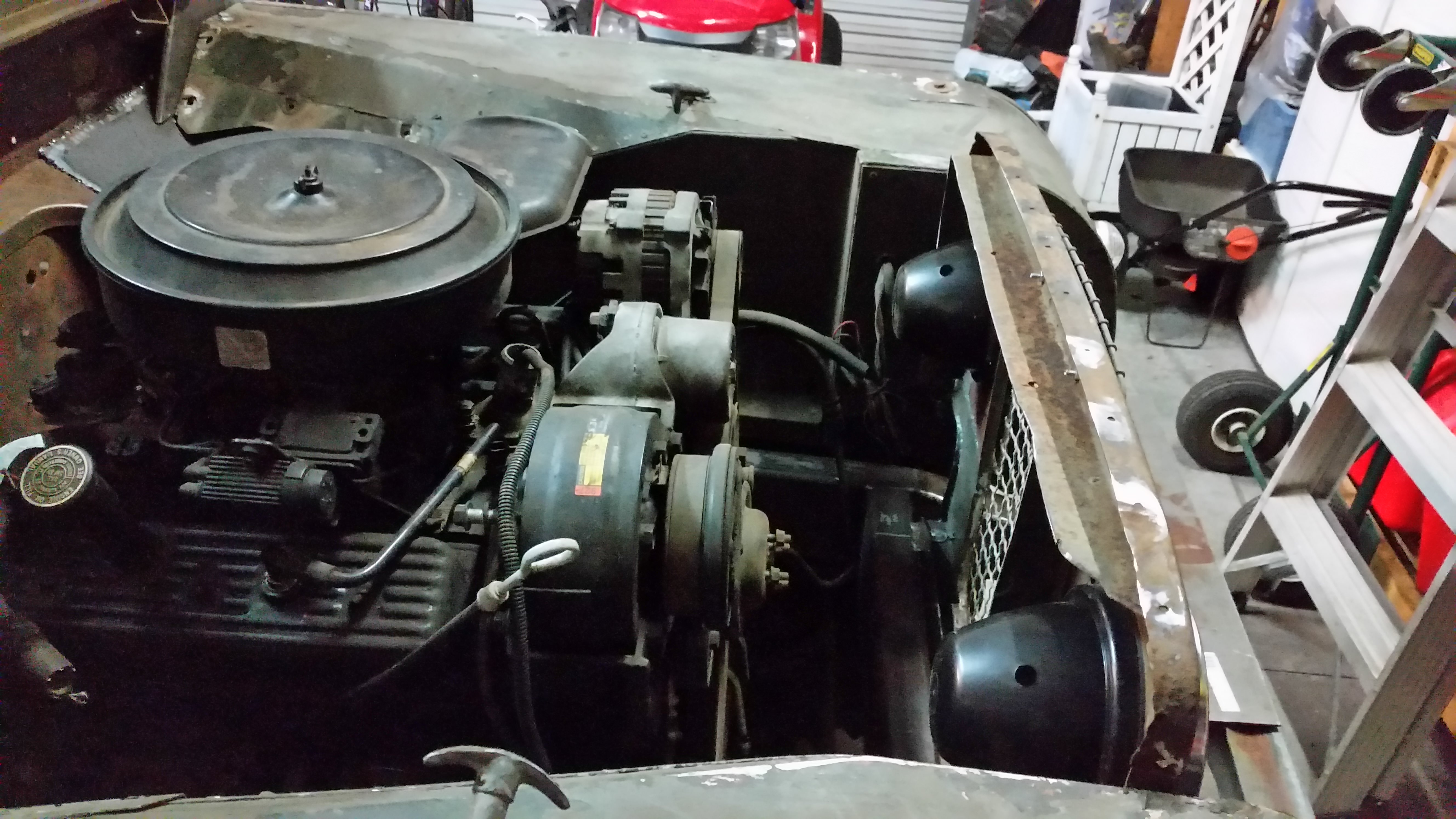

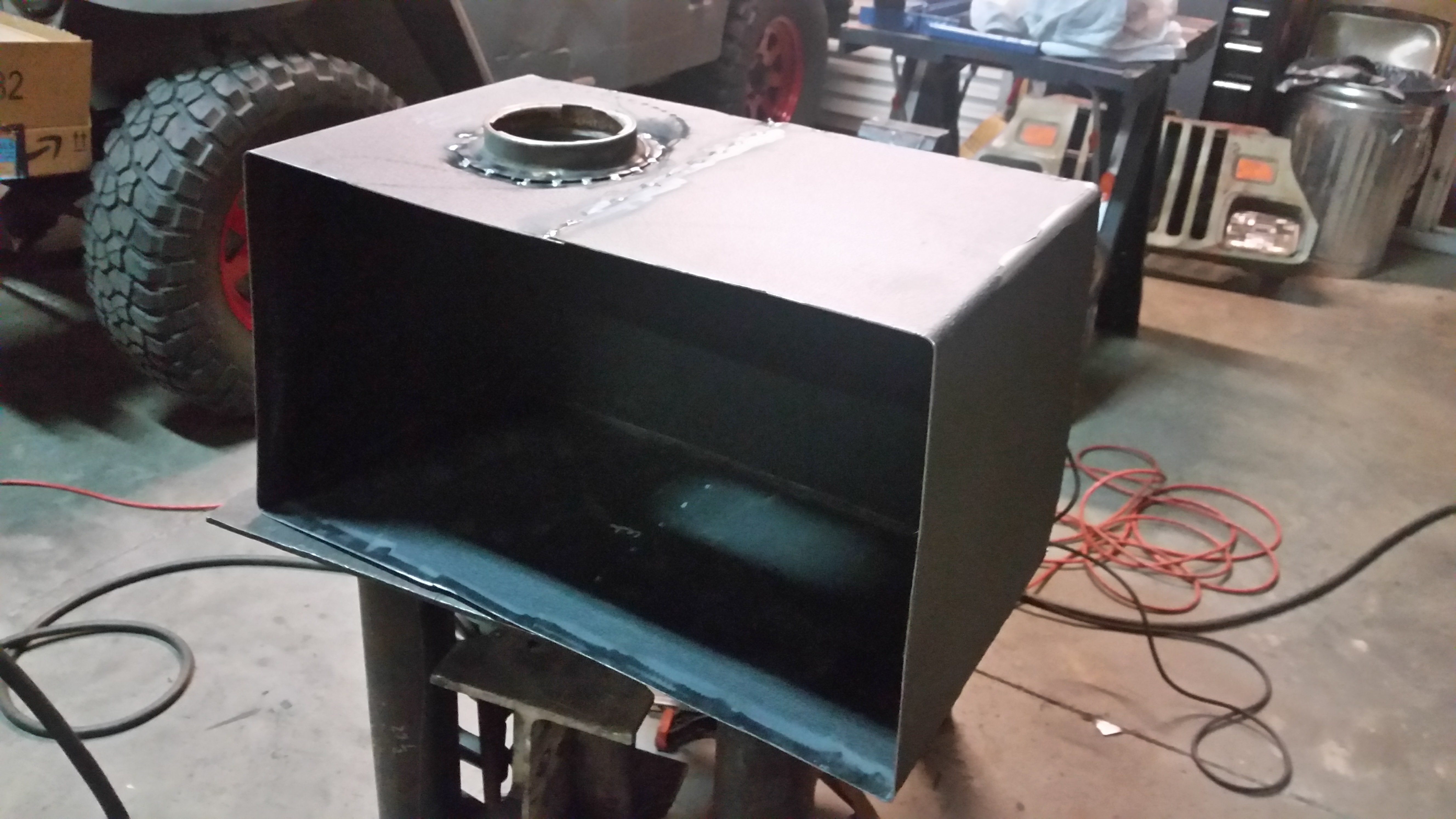

Well i put the hoist to work today and just placed the engine and gear boxes in the frame to do some rough measurements and see what I am dealing with. I will have to play the rear driveshaft game. Original rear shaft is 24 inches, i can get that with this combo. I might have to trim the grill more and run an electric fan but I am not opposed to that. This week i will get to making a crossmember to help mock it up and see what i have to make motor mounts. It does fit nice between the rails, Exhaust looks like it will clear pretty good.

I will have to think about the transfercase shifters, they are gonna be in a touch location. I have to look into doing something like a dana 20 and try to get the shifters farther forward of the stock location so i dont have to hack the seat riser box. Baby steps I guess.

I will have to think about the transfercase shifters, they are gonna be in a touch location. I have to look into doing something like a dana 20 and try to get the shifters farther forward of the stock location so i dont have to hack the seat riser box. Baby steps I guess.