orange150

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Fairfax City, VA

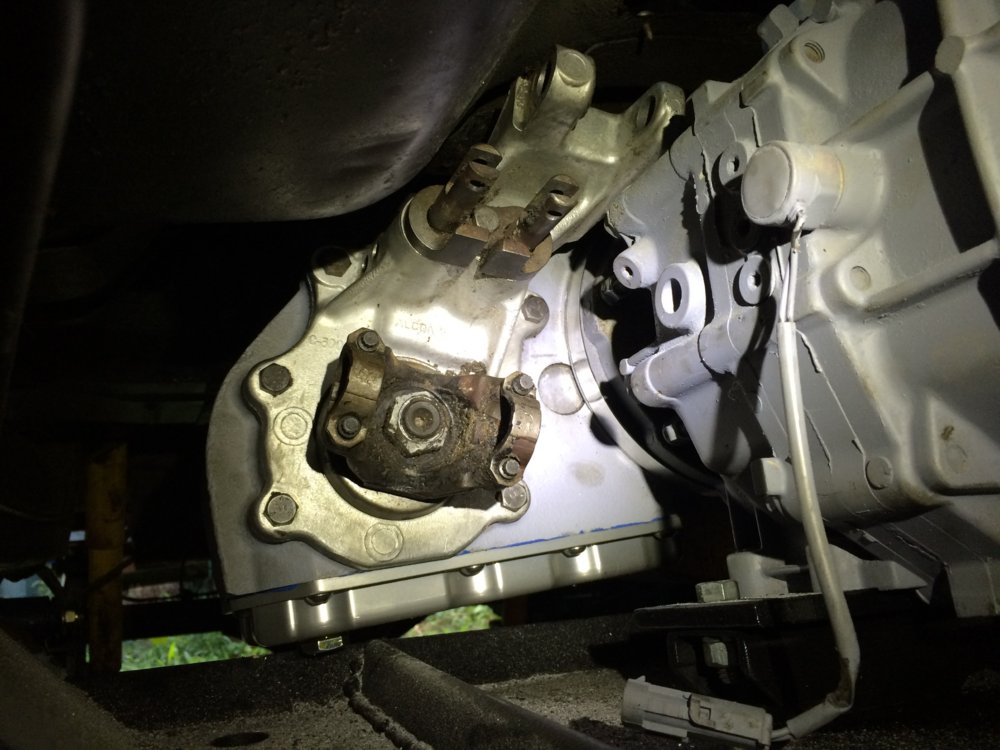

D300 mounted up. The fit is tight. So tight in fact that I can't fit any off the shelf transfer case shifter. More on that later.

--------------

One thing about this that I hope to correct whenever I get someone to fab up an independent trans mount - the Barnes skid plate is made to fit the CJ (duh), so the additional length of the AX15 combo becomes a problem. By shear dumb luck I clocked the D300 up enough that all I had to do was notch the skid plate a little to give me some buffer. So far I haven't seen any signs of contact. Whenever the aforementioned fab work happens I will get another Barnes plate but get him to make me one with an additional 3 or 4 inches added on the rear.

--------------

One thing about this that I hope to correct whenever I get someone to fab up an independent trans mount - the Barnes skid plate is made to fit the CJ (duh), so the additional length of the AX15 combo becomes a problem. By shear dumb luck I clocked the D300 up enough that all I had to do was notch the skid plate a little to give me some buffer. So far I haven't seen any signs of contact. Whenever the aforementioned fab work happens I will get another Barnes plate but get him to make me one with an additional 3 or 4 inches added on the rear.

Last edited: