mcutler

Well-Known Member

- Joined

- Apr 17, 2010

- Location

- mt.airy nc

I decided I will not borrow money to buy any more work trucks. 6 yrs, 220,00 miles, one rebuilt motor, and still have a few payments left on the 08 Chevy 3500.... Aside from the motor rebuild, haven't spent a nickel on the truck other than maintenance. Therefore I have decided to build my next truck.

Don't wanna start a manufacturers debate with this thread. I've done my research, weighed all the pros and cons, and everyone has their own opinions.

Originally was going to go old school with square body Chevrolet and 12 valve. I decided that the 30 yr old chassis wouldn't be safe, in the long term, towing upwards of 26k on a daily basis. My choice was made by economics and opportunity.

Platform- '08 f450 c&c, 6.4, 200k powrstroke, 4x4, auto, 19.5" wheels, and a purpose built flatbed, base model interior.

Plan- initially i had considered doing a crd 24 valve cummins. Through research I determined it not to be a cost worthy approach. So after talking to reputable diesel engine builders and aftermarket support manufacturers, I decided to use the 6.4.

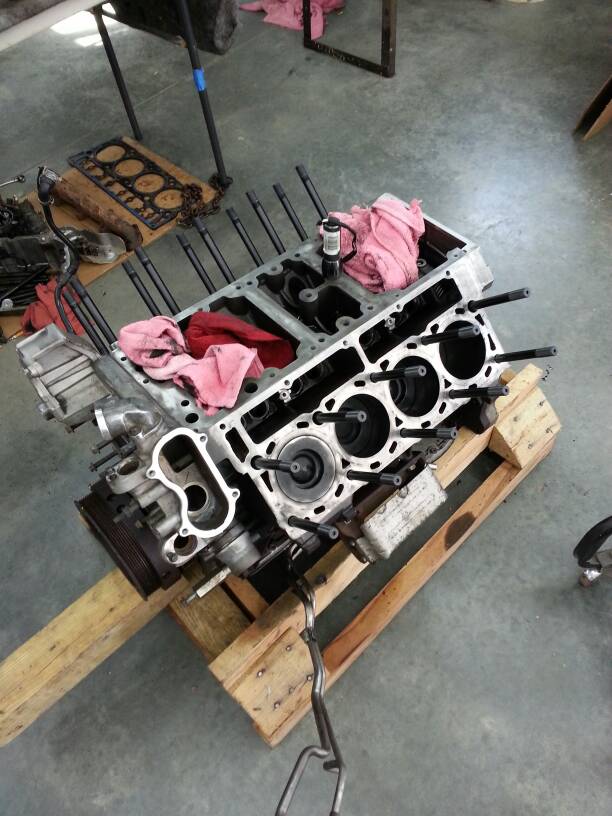

Engine build plan- I purchased a low mileage motor, 90k- for a song. Bad news is it had fuel delivery issues- no surprise there. Motor currently in truck had 200k and lifter issues.

Bottom end on replacement motor is strong , good cross hatch on all cylinder walls, and tight crank.

New Parts list for newer motor-

Arp head studs, gaskets, lifters, rockers, push rods, hpfp, all fuel lines, upper gasket set, hd up pipes, oil cooler, water pump, tstats, belts, idlers, radiator hoses, lift pump, rear main, cold air charge tube, intercooler boots, s&b intake, dpf delete pipe & egr delete, h&s mini maxx race tuner. Not trying to build a hot rod but a long term dependable truck.

Rebuilt parts- both turbos, injectors, steam cleaned intake, heads fluxed and resurfaced, cleaned intercooler and hot side tube, relined fuel tank.

Fabricated parts- flat bed with trick removable metal side boards and tailgate, class 5 hitch, led lighting in tail and headache rack.

This is not a trick fab build so much as just sharing what I'm working on.

Few pics

Don't wanna start a manufacturers debate with this thread. I've done my research, weighed all the pros and cons, and everyone has their own opinions.

Originally was going to go old school with square body Chevrolet and 12 valve. I decided that the 30 yr old chassis wouldn't be safe, in the long term, towing upwards of 26k on a daily basis. My choice was made by economics and opportunity.

Platform- '08 f450 c&c, 6.4, 200k powrstroke, 4x4, auto, 19.5" wheels, and a purpose built flatbed, base model interior.

Plan- initially i had considered doing a crd 24 valve cummins. Through research I determined it not to be a cost worthy approach. So after talking to reputable diesel engine builders and aftermarket support manufacturers, I decided to use the 6.4.

Engine build plan- I purchased a low mileage motor, 90k- for a song. Bad news is it had fuel delivery issues- no surprise there. Motor currently in truck had 200k and lifter issues.

Bottom end on replacement motor is strong , good cross hatch on all cylinder walls, and tight crank.

New Parts list for newer motor-

Arp head studs, gaskets, lifters, rockers, push rods, hpfp, all fuel lines, upper gasket set, hd up pipes, oil cooler, water pump, tstats, belts, idlers, radiator hoses, lift pump, rear main, cold air charge tube, intercooler boots, s&b intake, dpf delete pipe & egr delete, h&s mini maxx race tuner. Not trying to build a hot rod but a long term dependable truck.

Rebuilt parts- both turbos, injectors, steam cleaned intake, heads fluxed and resurfaced, cleaned intercooler and hot side tube, relined fuel tank.

Fabricated parts- flat bed with trick removable metal side boards and tailgate, class 5 hitch, led lighting in tail and headache rack.

This is not a trick fab build so much as just sharing what I'm working on.

Few pics