YJJPWrangler

Well-Known Member

- Joined

- Jul 19, 2005

- Location

- Charlotte

Ordered a 4x8 sheet of 1/4 and a stick of 1.5x.120 dom from race city and picked it up friday. I figured a simple belly skid would be easy to fab and mount up.

Wrong. Stopped by @getstucksome house on Saturday and put a game plan together. I’m planning on redoing the trans crossmember and anti wrap crossmember. That should allow me to push the drivetrain up another 2” or so and give me a flatter belly.

Got the rear crossmember pulled this morning and that’s when I found of the trans mount studs was bent. Only way to replace it is to pull the transfer case.

Now that the case is out, I might as well leave it on jackstands and do more fun things.

I think I’ll be able to easily fab new crossmembers that are higher than the originals. I was never happy with the originals so this is a good chance to redo them.

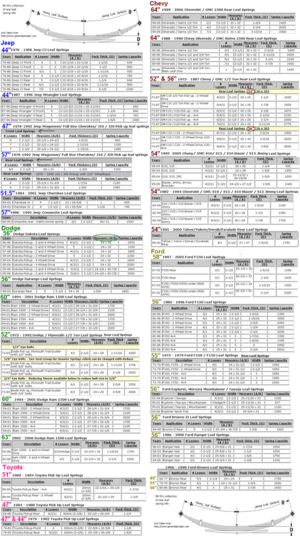

Plan is to flip the rear springs, that will net me around 7.5” of additional wheelbase. I’m currently sitting around 90ish so this is gonna be a huge help. Driveshaft will be dropped off at Olivers again to get lengthened. There is a possibility that the rear differential will now contact the gas tank. Once I cycle the suspension and confirm that it does, I’ll be ordering a new tank to go in the rear. Hopefully it doesn’t, rough math puts it close but clear.

Once it’s all put back together, I’ll be looking for a set of chromos and larger tires. I’m thinking something in the 38-39” flavor.

Wrong. Stopped by @getstucksome house on Saturday and put a game plan together. I’m planning on redoing the trans crossmember and anti wrap crossmember. That should allow me to push the drivetrain up another 2” or so and give me a flatter belly.

Got the rear crossmember pulled this morning and that’s when I found of the trans mount studs was bent. Only way to replace it is to pull the transfer case.

Now that the case is out, I might as well leave it on jackstands and do more fun things.

I think I’ll be able to easily fab new crossmembers that are higher than the originals. I was never happy with the originals so this is a good chance to redo them.

Plan is to flip the rear springs, that will net me around 7.5” of additional wheelbase. I’m currently sitting around 90ish so this is gonna be a huge help. Driveshaft will be dropped off at Olivers again to get lengthened. There is a possibility that the rear differential will now contact the gas tank. Once I cycle the suspension and confirm that it does, I’ll be ordering a new tank to go in the rear. Hopefully it doesn’t, rough math puts it close but clear.

Once it’s all put back together, I’ll be looking for a set of chromos and larger tires. I’m thinking something in the 38-39” flavor.