Yall are giving Mr Fuller a hard time for no reason. He's a good hard working God fearing man doing the best with what he has at his disposal.

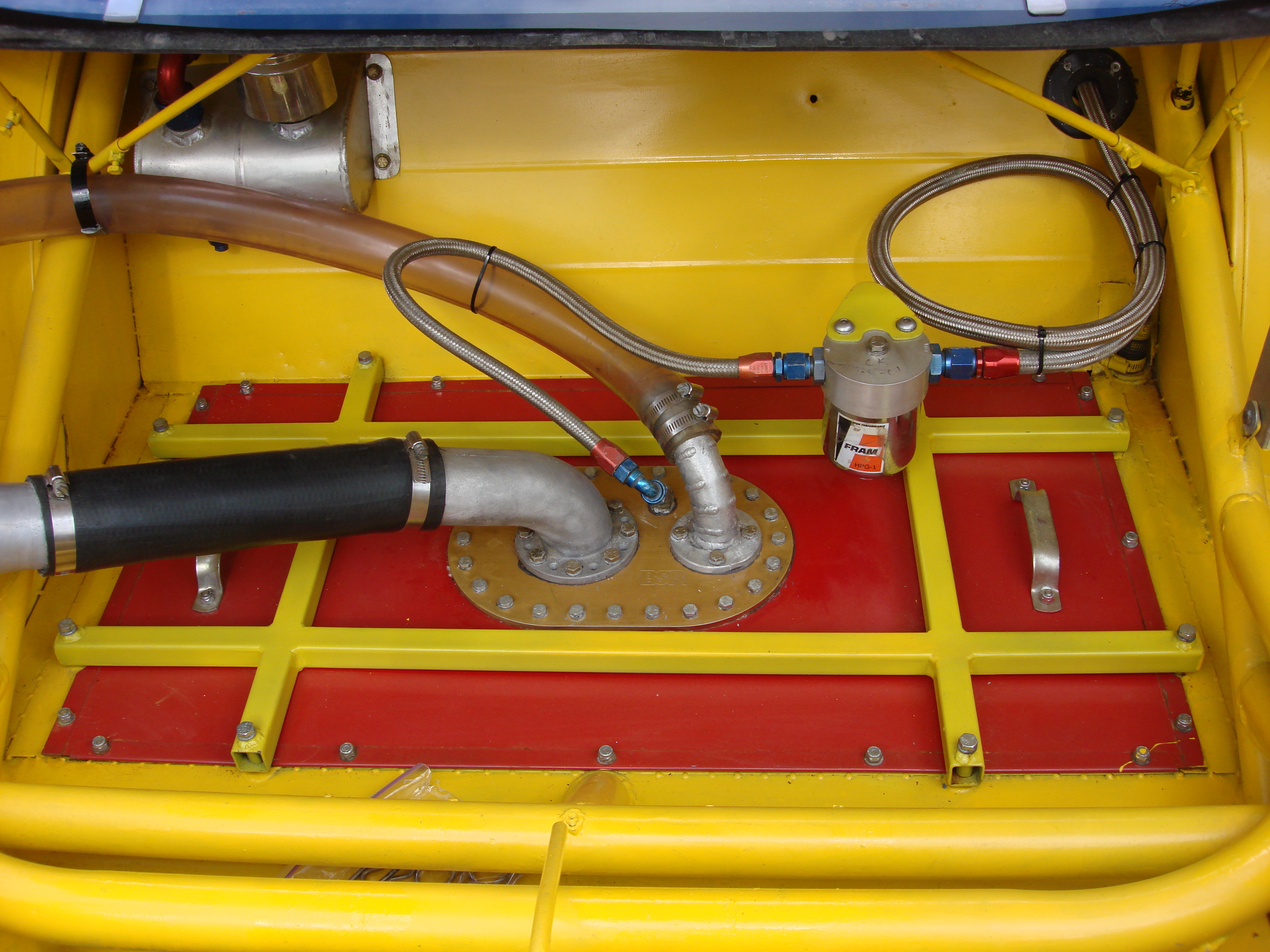

It's not a bad gas tank mount.

Looks like he used 16d nails to attach the boards not cheap 8d stuff.

Plus he has at least 4 strap hangers

Maybe 6 can't tell from the pics.

Plus like 2-3 screws per strap. That's a lot of holding power. Perforated hanging strap has a working weight ratingbof 50lbs. So with 4 it should hold at least, what 2o0lbs? And no way that tank weighs that much. I mean the tank weighs 40lbs, maybe,? Add in 20 galllons of gas at 7lbs per gallon..that's still only 180lbs.

Plus gravity is holding that tank down, it's not like it will fly away.

The only two concerns I have, and they are minor to be sure:

1- there appears to be a strap and screw near the rear seat belt. I'd make sure the belt couldn't rub on that...safety first

2- there are only 2 straps running front to back, so if he stopped quickly only those two straps prevent the tank from moving forward.

So since force =mass*acceleration. And the tank weighs 280(above estimate) let's say he suddenly applied brakes and went from 10miles per hour to zero in 1 second. That is an acceleration (deceleration) of 52,800 feet per hour per second or 14.667 ft

So we will use 14 for our acceleration value.

280 * 14 = 3,920 lb ft of force.

Since the straps are rated at 50lbs..in the above stopping scenario he would be a few straps short. Adding about 76 more straps front to rear only should make this perfectly safe.

@shawn or

@jeepinmatt or

@Fabrik8 can check my math