Seat Heaters:

The price to get good quality seat heater kits to install inside the original seats was getting close to the price for new Wet Okole waterproof neoprene seat covers with built-in heaters, so I bought new seat covers to freshen up the interior. The original Nissan neoprene seat covers are starting to show their age.

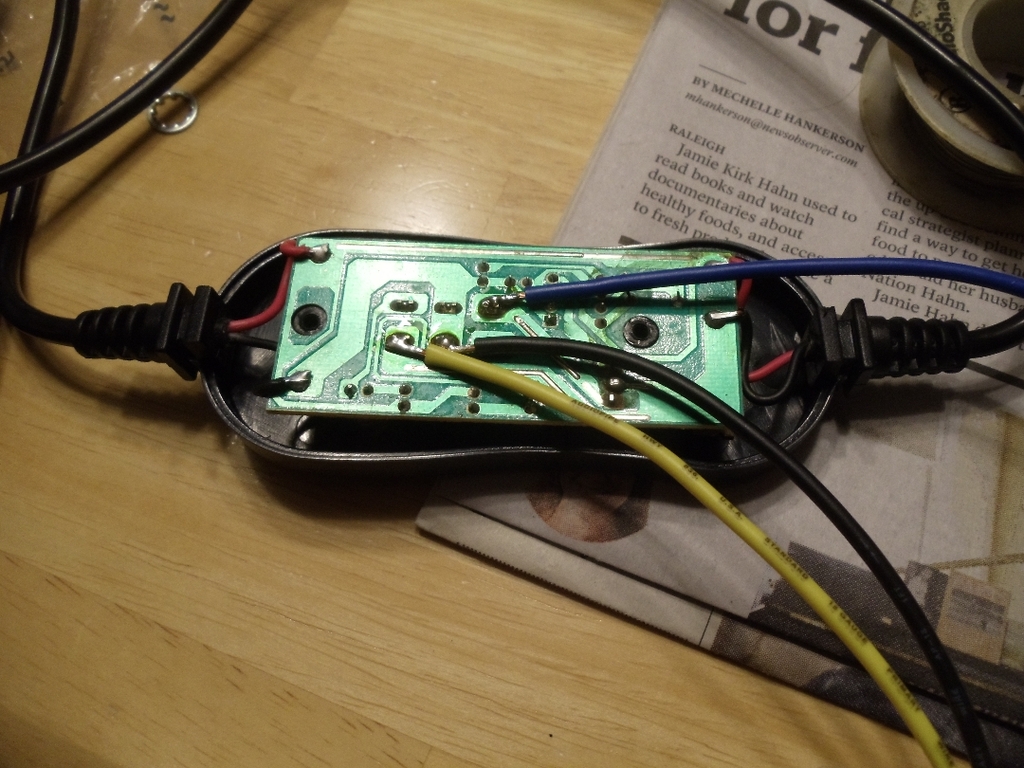

They arrived with pendants to plug into 12V sockets but I wanted a built-in setup instead. With that in mind I tore open the pendants, traced out the wiring, and tapped the circuits to so I could build a harness to run them with switches mounted in the console.

I bought some neat two-color LED seat heater switches off of Amazon, some relays from Radioshack, and wired and installed the whole thing inside the wasted space under the console. I used colored wire so I could have a color code for the harness. Everything was done from scratch.

With the switches on the console and the circuit powered by an ignition hot I can use them when the engine is running and they turn off when I kill the ignition.

Completed:

The price to get good quality seat heater kits to install inside the original seats was getting close to the price for new Wet Okole waterproof neoprene seat covers with built-in heaters, so I bought new seat covers to freshen up the interior. The original Nissan neoprene seat covers are starting to show their age.

They arrived with pendants to plug into 12V sockets but I wanted a built-in setup instead. With that in mind I tore open the pendants, traced out the wiring, and tapped the circuits to so I could build a harness to run them with switches mounted in the console.

I bought some neat two-color LED seat heater switches off of Amazon, some relays from Radioshack, and wired and installed the whole thing inside the wasted space under the console. I used colored wire so I could have a color code for the harness. Everything was done from scratch.

With the switches on the console and the circuit powered by an ignition hot I can use them when the engine is running and they turn off when I kill the ignition.

Completed:

Good luck, and nice build!

Good luck, and nice build!