maulcruiser

Well-Known Member

- Joined

- Aug 13, 2005

- Location

- Bladenboro/Wilmington, NC

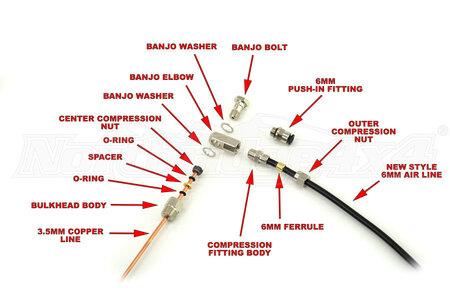

I had to pull my 3rd member on my 8.4 Toyota as the ARB was pressurizing the housing. I could hear and feel air escaping from the vent. Of course, this all occurred after the diff was out of warranty. I just pulled the 3rd yesterday evening, so I've not sourced the air leak. Is there a common seal that fails? ECGS replaced the gears in the 3rd last year, but I didn't have it plumbed on the truck at that time to know if it was an issue. It can't be too much involved to bench test, right? Looking at ECGS's website, there's a seal housing, two o-rings, and a bulkhead o-ring that it could possibly leak from. The copper line appears intact and doesn't have any witness marks from rubbing. I'm in uncharted territory here, but with the videos online, it seems simple enough. Any further advice anyone could offer?