NickMaul

Well-Known Member

- Joined

- Jul 4, 2009

- Location

- Norfolk, VA

I put in a lot of hours to try and make a CTB ride but the dana 300 wasn't having it. Blowing oil out of the vent hose line like crazy. Pretty sad but at least the big work is done. A few finishing touches and I won't have to work on this anymore. Mainly painting everything since it already has a little surface rust on it.

So the rear seats will just barely sit in their normal spot. I believe the latch is off by a inch or so. I can't remember the last time someone even sat in my back seat but it should still be comfortable enough.

The shifters sat in the old shifter spot. A little tight around the knee area but overall not too bad. Have to seal up the hole where I cut it to keep the cab a little quieter. I can hear all the gear noise from the tcase and trans now (I kind of like it )

)

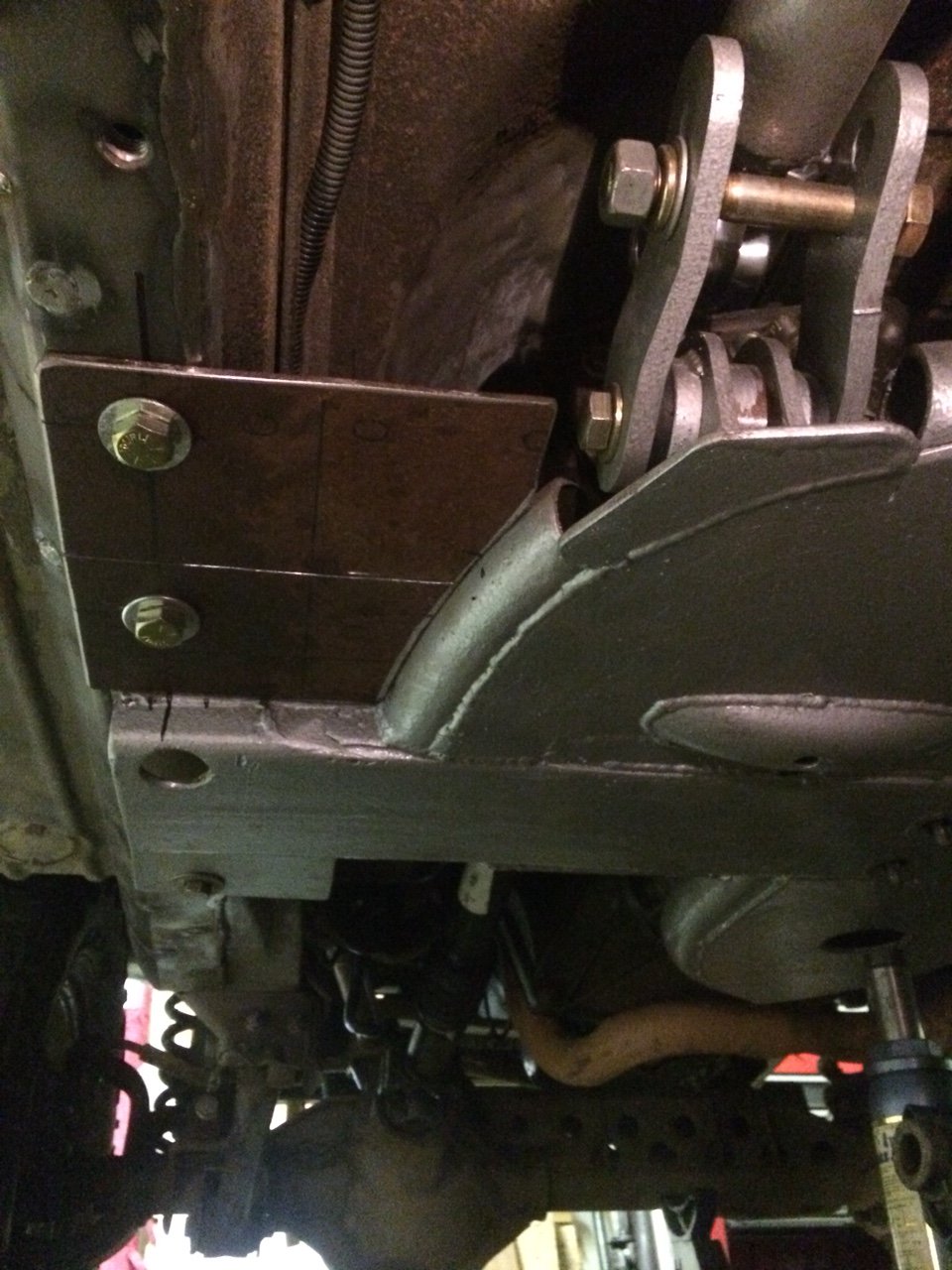

My last big fabrication project I had to do from the stretch was a traction bar. I was on the fence about it at first but now I feel good it is in there. I only have 3"-4" lift over stock so packaging was a little interesting. Had to clearance on spot on the floor pan. It isn't very ideal, maybe if it were a radius arm, but the bottom tube is 2" round 1/4" thick so me thinks this should hold up fine.

Long term goal for this jeep is to slow down the time I work on it and the money I spend. Realistically I want to buy a bunch of DOM and starting bending some tube for a hybrid cage. Maybe during the winter I can try to knock that out. For now I want to wheel

So the rear seats will just barely sit in their normal spot. I believe the latch is off by a inch or so. I can't remember the last time someone even sat in my back seat but it should still be comfortable enough.

The shifters sat in the old shifter spot. A little tight around the knee area but overall not too bad. Have to seal up the hole where I cut it to keep the cab a little quieter. I can hear all the gear noise from the tcase and trans now (I kind of like it

)

)

My last big fabrication project I had to do from the stretch was a traction bar. I was on the fence about it at first but now I feel good it is in there. I only have 3"-4" lift over stock so packaging was a little interesting. Had to clearance on spot on the floor pan. It isn't very ideal, maybe if it were a radius arm, but the bottom tube is 2" round 1/4" thick so me thinks this should hold up fine.

Long term goal for this jeep is to slow down the time I work on it and the money I spend. Realistically I want to buy a bunch of DOM and starting bending some tube for a hybrid cage. Maybe during the winter I can try to knock that out. For now I want to wheel