YJJPWrangler

Well-Known Member

- Joined

- Jul 19, 2005

- Location

- Charlotte

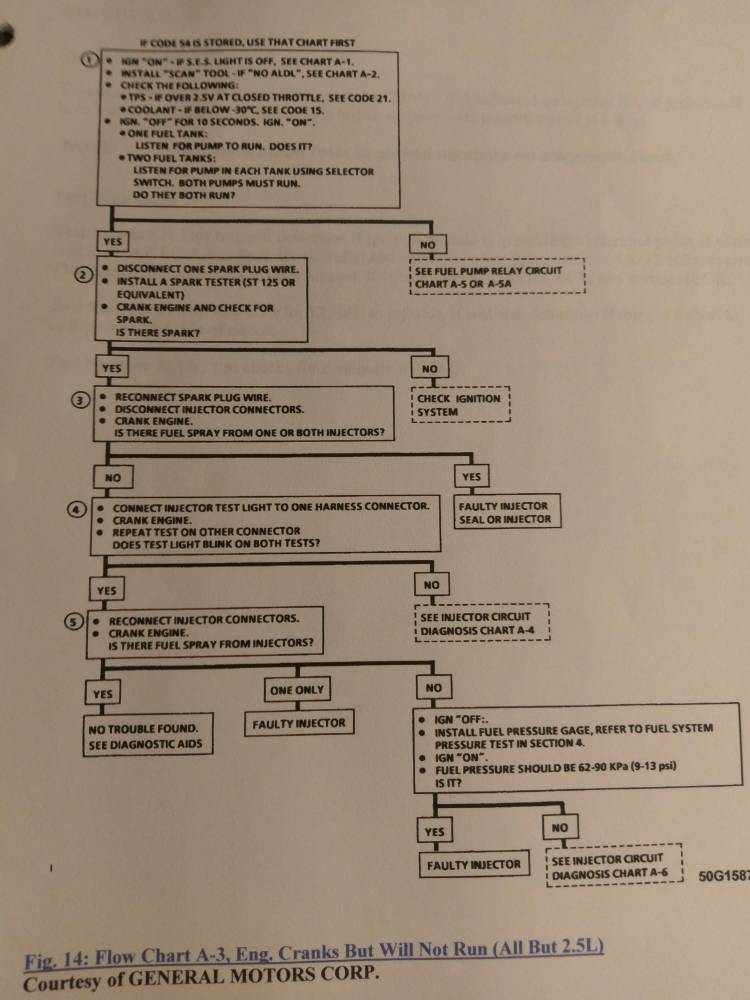

Got the fuel pump installed today and it works correctly. Issue is the drivers side injector(new) is dumping fuel into the TBI. Passenger side injector(old) is not doing anything. Could it be a bad pressure regulator? Or a stuck injector? Is it possible for a new injector to be stuck open? I am running a Carter P5000 external fuel pump. This was the recommended pump off Pirate and other sites. Motor is a 91 4.3l out of an S10. Any thoughts?