mcutler

Well-Known Member

- Joined

- Apr 17, 2010

- Location

- mt.airy nc

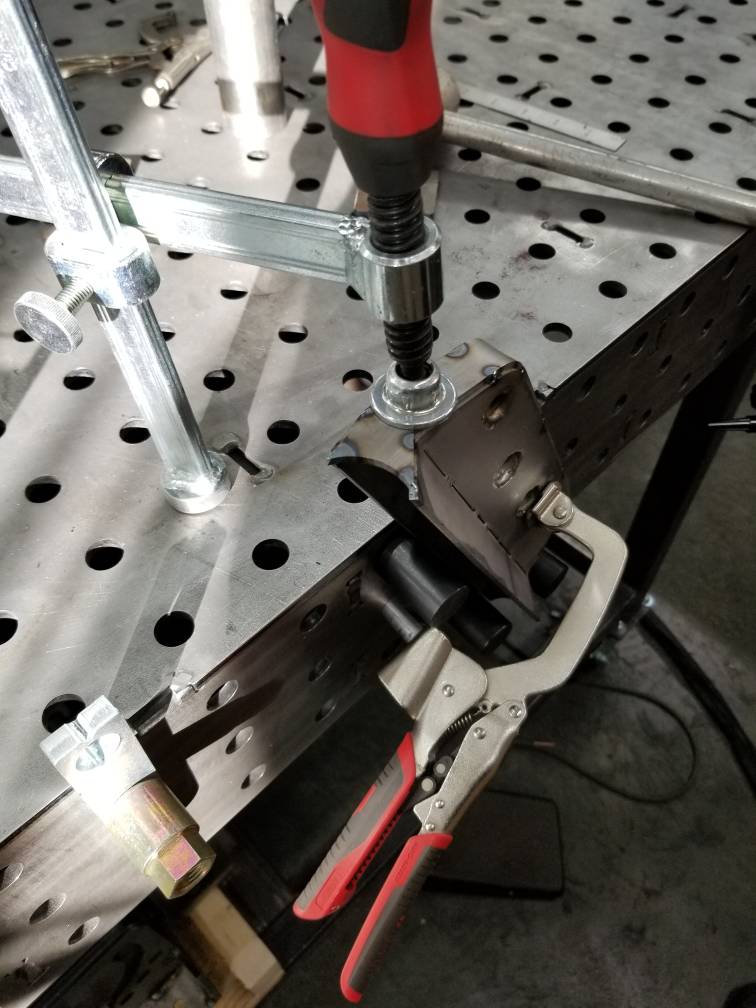

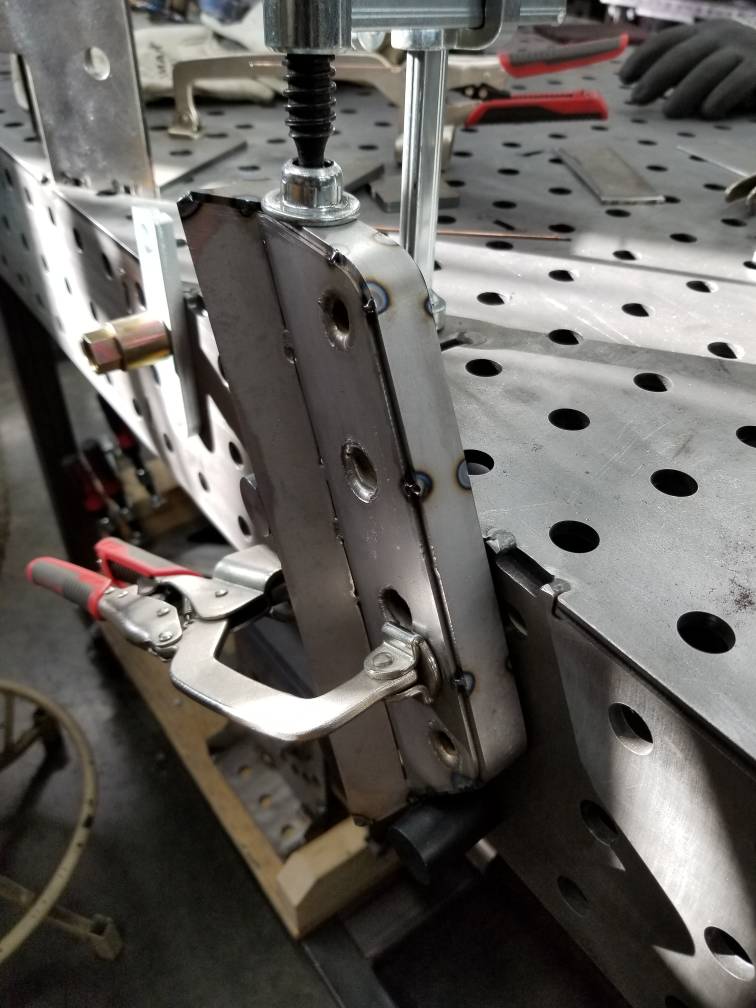

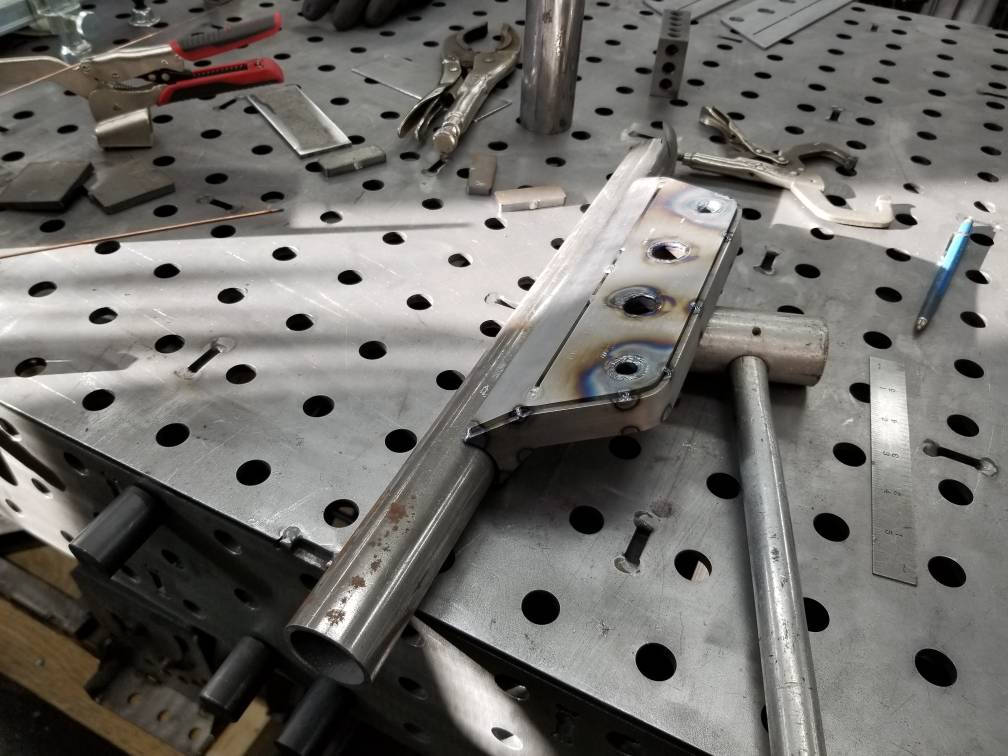

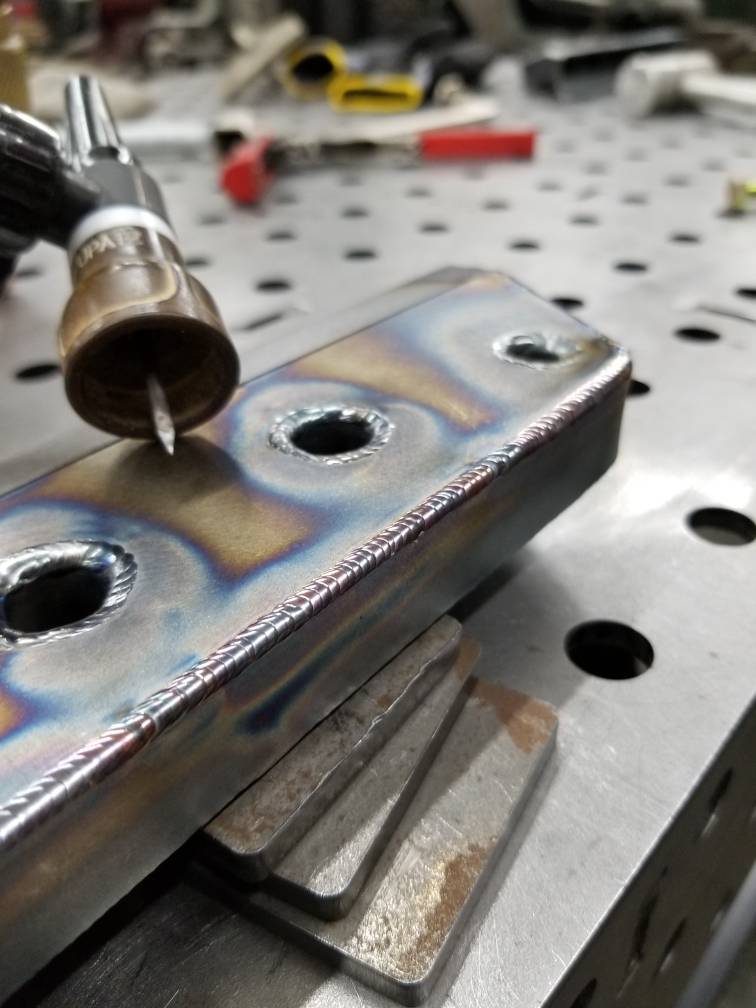

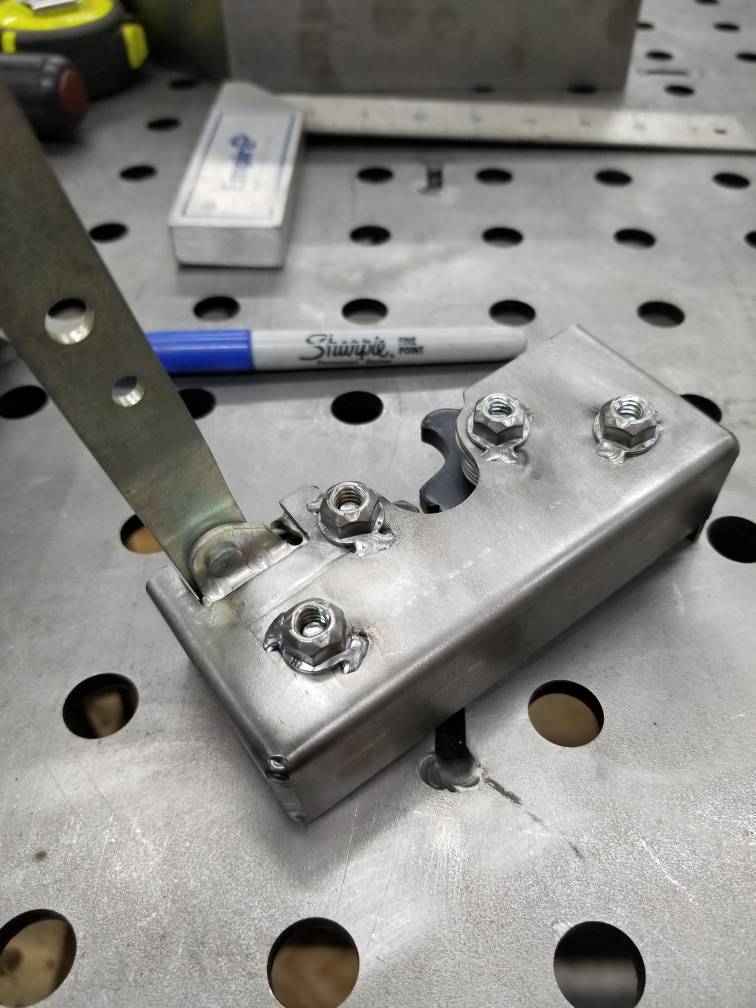

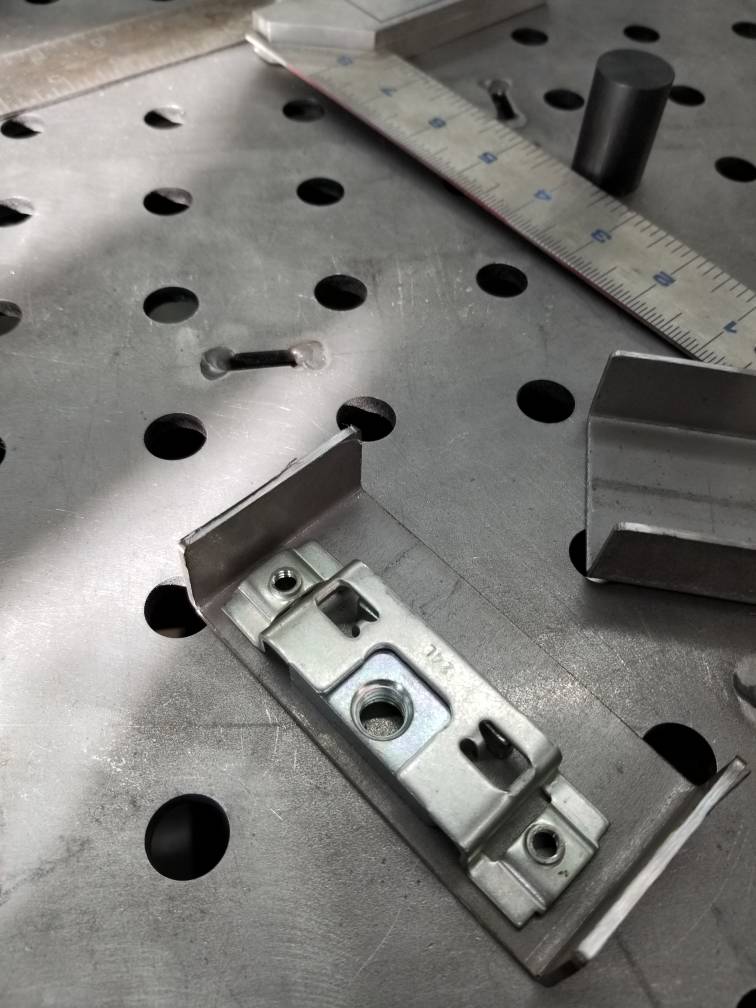

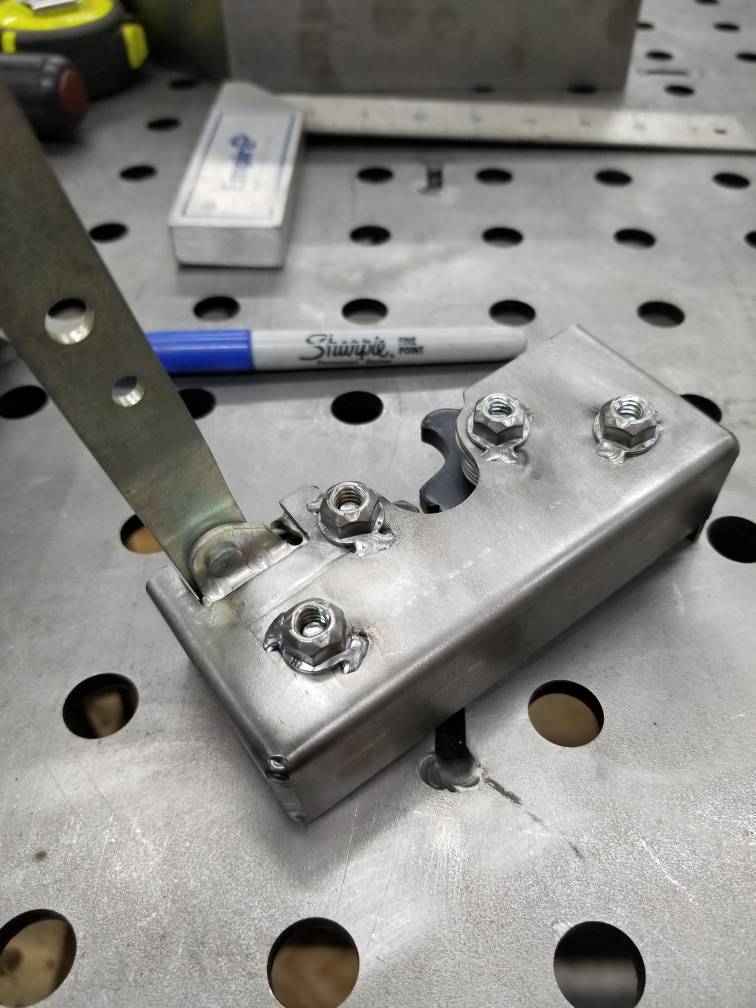

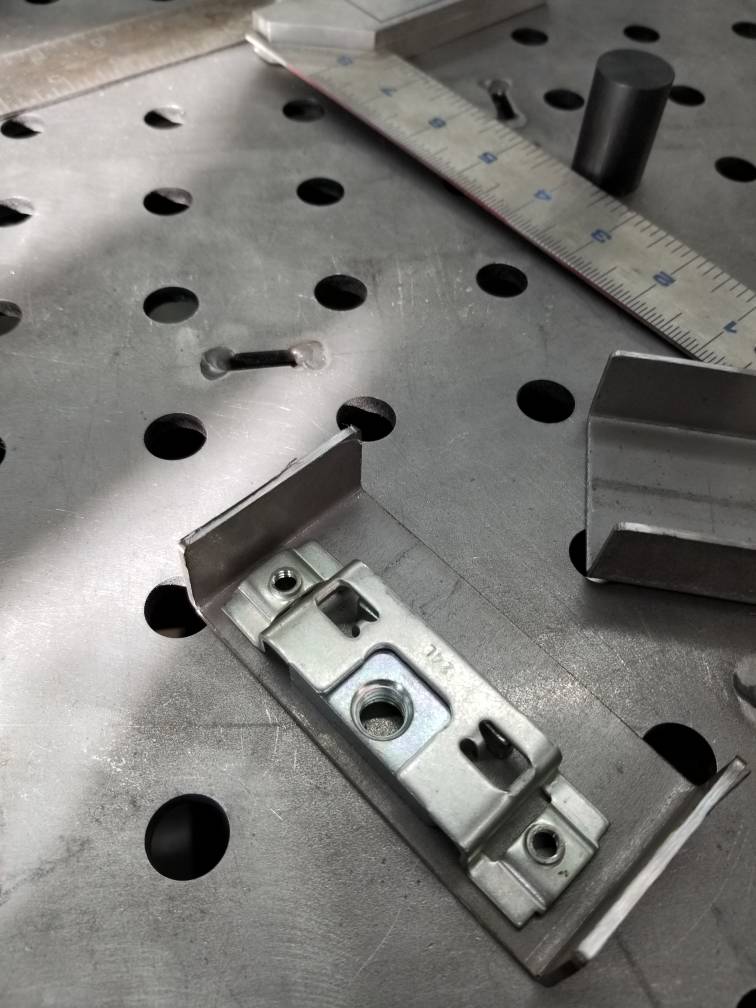

Doors latched. Still need to make a paddle for the release lever. I set it up to pull up to release.

Cutlerfab

Sent from my SM-G892A using Tapatalk

Cutlerfab

Sent from my SM-G892A using Tapatalk