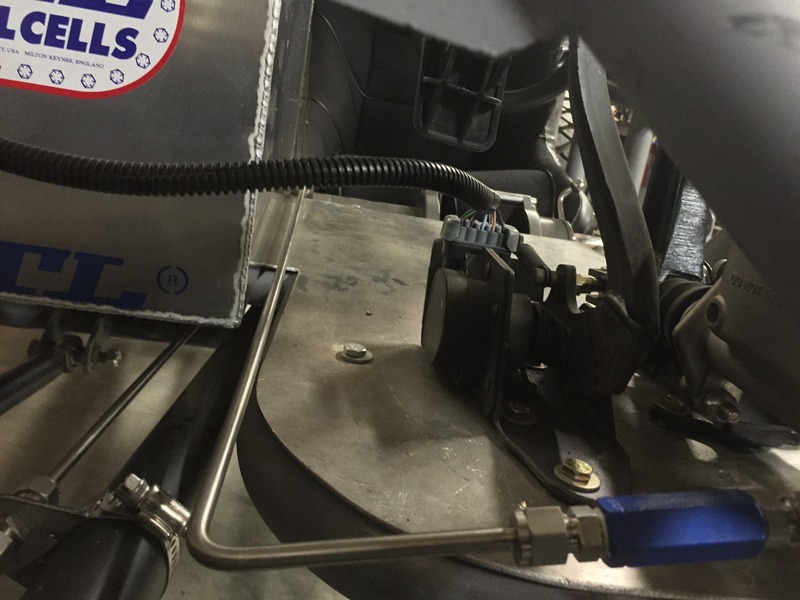

Here's a few more progress pics from the last couple days. A lot of time was spent just mapping out in my head how all the wiring and plumbing is going to be routed and tacking on zip tie tabs etc. to secure everything. I did get a few more things done though.

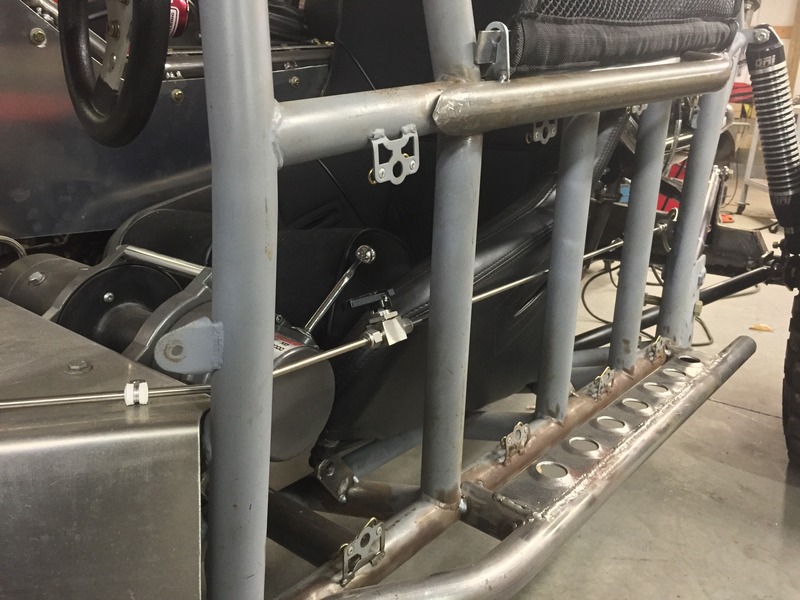

I welded up and painted the fire extinguisher mounts I got from JDuck. These things are really nice, you can't beat them for the money. I'm going to mount one inside where I can reach it while i'm strapped in, and one in the back around the motor somewhere. I'm thinking I'll probably go with the ColdFire extinguishers.

I also rolled the axles out from under it and installed the 3rd members. I tried doing it with the axles still under the buggy, but it was just way easier this way and they had to come out anyway.

I also assembled the front axle shafts. The joints are CTMs. The outers are custom CTM 300M 2nd gen Dodge 33 spline unit bearing style stubs, and the inners are Moser 35 spline chromos. One day I'll probably order some CTM inners to match. (The front shafts, no joints, came with the chassis when I bought it as a roller) Both are machined for 50* steering. I still have to install the shafts and cycle the ram though to see how much angle I can use and whether or not I need to de-stroke the ram.

And here's the rear axle shafts, I got these in a long time ago, but I'm not sure if I ever posted any pics of them. They're custom length CTM 300M 35 spline double splined shafts with CTM 300M drive flanges.

Hopefully I won't be breaking any axle shafts, but ring & pinions will probably hate me though.

I'm hoping it won't be too long before I tear it all apart and start welding and painting. I'm still trying to order up the rest of the parts I need here and there when the wallet allows. I got my ORI dual fill kit and a bunch of AN hose and fittings last week. I ordered my nitrogen regulator for the fill kit this week along with some other small parts. I still have some wiring stuff to order too, and then I'm sure there will be several things that I'll remember at the last minute that I need.