marty79

Well-Known Member

- Joined

- Dec 2, 2015

- Location

- Newton, NC

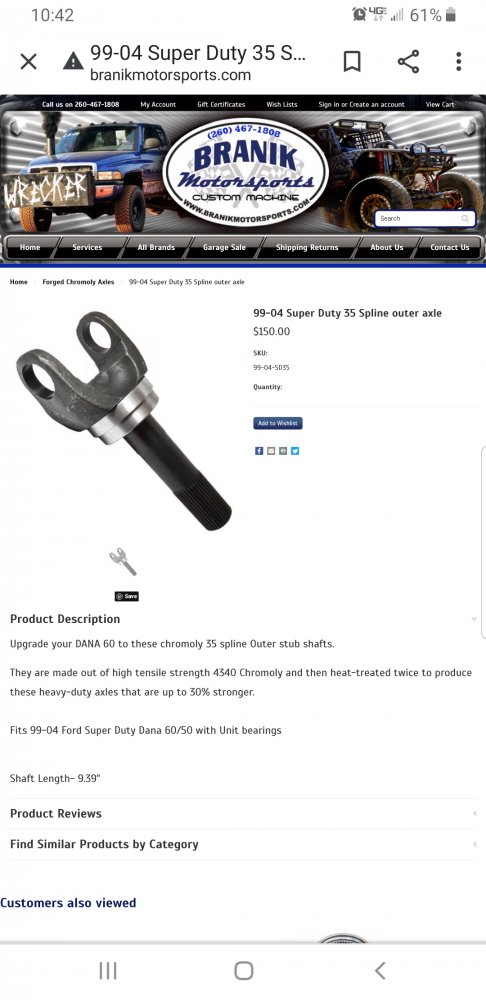

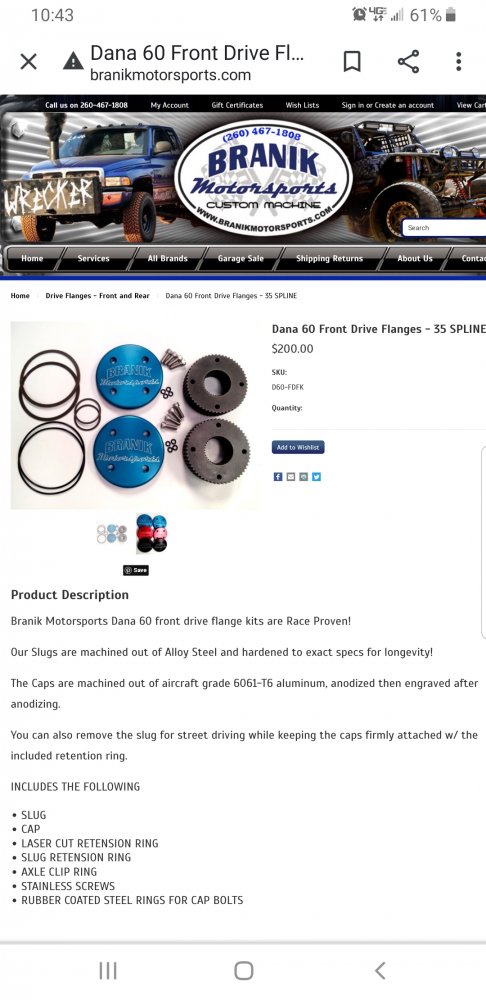

Hey everyone is this what is needed to really upgrade the weak links on my front axle. My driveshaft are all beef so seems the 30 spine outers would be first to go from what I've heard ...thanks for the input