You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tube Bending Help: plane of bend

- Thread starter BigBody79

- Start date

Scooter402

Ruffling feathers and shaking trees

- Joined

- Feb 4, 2009

- Location

- Livin in an Amish Paradise

I'm assuming you mean multiple bends in the same tube? I'd use an accurate digital level or angle finder (NOT a bubble level...nowhere near accurate enough), or go ol' skool and use an adjustable height stand under the bent end. Set it up under the tube before it's bent so it's at the correct height, then you have a distance reference to the floor. That is, if your floor is perfectly level.

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

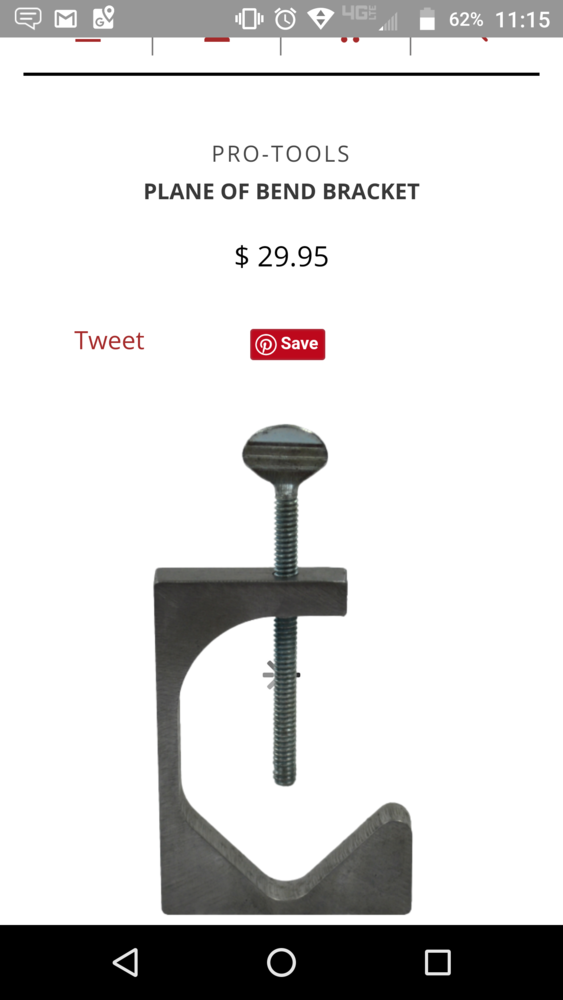

Feeding through or flipping it? Buy or make a clamp on plane of bend gauge. Bend one side. Clamp on. Set to zero. Feed through or flip. Align to zero. Bend next bend. On long stuff if your die is horizontal like mine, support the ends. Weight will pull it down and off as it cycles. Slightly, but some.

braxton357

Robot

- Joined

- Apr 6, 2005

- Location

- Morganton

What ^ he said. This the one I use with a digital angle finder, but like WW said you can easily make one and put a regular angleometer on it.

- Joined

- Mar 13, 2005

- Location

- Raleigh, NC

You can always shim the bender until it's plumb. That might make some things easier.

rockcity

everyday is a chance to get better

- Joined

- Apr 10, 2005

- Location

- Greenville, NC

Patience

catfishblues

Well-Known Member

- Joined

- Jul 26, 2005

- Location

- Pfafftown, NC

https://www.amazon.com/Wixey-WR300-...coding=UTF8&psc=1&refRID=YGZPSZJX69SNMD795JE4

I have the HF version. It's worked well for me for several years. Set your zero off the die. Make your bend. Move to next bend location. Attach the angle gauge to the bent end and adjust until the gauge zeros out again. You should be parallel at that point. My bender is set up to bend in the vertical plane, I think this makes it much easier. You don't have the bend trying to pull itself to the ground.

I have the HF version. It's worked well for me for several years. Set your zero off the die. Make your bend. Move to next bend location. Attach the angle gauge to the bent end and adjust until the gauge zeros out again. You should be parallel at that point. My bender is set up to bend in the vertical plane, I think this makes it much easier. You don't have the bend trying to pull itself to the ground.

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

@catfishblues I wish my bender was in the vertical configuration. Way more advantages to being horizontal. Also the way my bender is designed it swings both working ends in an arc. I have contrived a way to support these ends by means of a rolling cart of sorts. One man band operation is truly a dance of epic proportions.

9 Steps to Eliminate Material Twist When Bending Tube or Pipe

I didn't realize the the tube twisted during the bend.

I didn't realize the the tube twisted during the bend.

catfishblues

Well-Known Member

- Joined

- Jul 26, 2005

- Location

- Pfafftown, NC

@catfishblues I wish my bender was in the vertical configuration. Way more advantages to being horizontal. Also the way my bender is designed it swings both working ends in an arc. I have contrived a way to support these ends by means of a rolling cart of sorts. One man band operation is truly a dance of epic proportions.

Wasn't hard to modify. It took me a few hours to make the frame. There was some guesswork and luck involved, but overall, it was a fairly straightforward operation. My bender is an ancient Hughes Engineering, the predecessor to the JD2 Model 3. Mr. Hughes still runs the company. I talked to him when I was buying a die, asking if his early design would work with the new style dies. He wasn't a big fan of the fact that I had it going vertical. I didn't care. I don't have to bolt it down, and I can swing a 10' bend in my narrow shop.

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

mine would be nearly impracticable to convert....

mcutler

Well-Known Member

- Joined

- Apr 17, 2010

- Location

- mt.airy nc

Vertical is the only way...

Sent from my SM-G925R4 using Tapatalk

Sent from my SM-G925R4 using Tapatalk

Wasn't hard to modify. It took me a few hours to make the frame.

Any photographs?

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

Creative cheap Ass approach when I was in a pinch. Problem is I've never replaced it with a better design.

catfishblues

Well-Known Member

- Joined

- Jul 26, 2005

- Location

- Pfafftown, NC

Any photographs?

I can try to get some better ones this afternoon.

mcutler

Well-Known Member

- Joined

- Apr 17, 2010

- Location

- mt.airy nc

500lb of shit in a 5 gal bucket...Any photographs?

Sent from my SM-G925R4 using Tapatalk

It looks like I am going to just make a vertical bender out of my JD2

I don't want to reinvent anything so I'm just going to copy some ideas. I really like the press/bender combo. I'll be doing that. It looks like @mcutler has the swag tools hydro mount and @catfishblues has the base/bottom mount.

I stole this picture from the for sale section because it is at a good angle credit to mcconnell

It looks like in the above posted benders that the C angle is not vertical but I can't tell what angle it is. Any particular reason for this?

As far as A & B. Where should the hydro cylinder mount in relation to the two bolts? This is the part I don't want to guess at.

I don't want to reinvent anything so I'm just going to copy some ideas. I really like the press/bender combo. I'll be doing that. It looks like @mcutler has the swag tools hydro mount and @catfishblues has the base/bottom mount.

I stole this picture from the for sale section because it is at a good angle credit to mcconnell

It looks like in the above posted benders that the C angle is not vertical but I can't tell what angle it is. Any particular reason for this?

As far as A & B. Where should the hydro cylinder mount in relation to the two bolts? This is the part I don't want to guess at.

- Joined

- Mar 13, 2005

- Location

- Raleigh, NC

So... @mcutler @catfishblues

When they're mounted vertically, how do you account for twist? If the bender is mounted horizontally, you can true the angle finder and measure the twist in the tube. If the die is mounted vertically, you can't measure how far to the left or right it is. Or.... can you?

When they're mounted vertically, how do you account for twist? If the bender is mounted horizontally, you can true the angle finder and measure the twist in the tube. If the die is mounted vertically, you can't measure how far to the left or right it is. Or.... can you?

mcutler

Well-Known Member

- Joined

- Apr 17, 2010

- Location

- mt.airy nc

No it's not vertical on mine. I set it up with a piece of 1.75" dom, at zero degrees start of bend with the tube set parallel to the ground, so that I would always have a true angle reading on the tubing on the bent end.It looks like I am going to just make a vertical bender out of my JD2

I don't want to reinvent anything so I'm just going to copy some ideas. I really like the press/bender combo. I'll be doing that. It looks like @mcutler has the swag tools hydro mount and @catfishblues has the base/bottom mount.

I stole this picture from the for sale section because it is at a good angle credit to mcconnell

It looks like in the above posted benders that the C angle is not vertical but I can't tell what angle it is. Any particular reason for this?

As far as A & B. Where should the hydro cylinder mount in relation to the two bolts? This is the part I don't want to guess at.

View attachment 261621

This will not work for every die or size, imho, at least it didn't on mine. So, I used the most popular die. I just have to remember to add or subtract when I change to the other size dies.... especially if I forget to adjust my degree pointer on the degree wheel.... but I usually just watch my digital angle finder.

-tip: when I'm running the die around to zero bend to seat the tube in the die, I crack the valve on the air cylinder enough to only seat the die, not start the bend... this lets me know I'm at zero.

Sent from my SM-G925R4 using Tapatalk

mcutler

Well-Known Member

- Joined

- Apr 17, 2010

- Location

- mt.airy nc

So... @mcutler @catfishblues

When they're mounted vertically, how do you account for twist? If the bender is mounted horizontally, you can true the angle finder and measure the twist in the tube. If the die is mounted vertically, you can't measure how far to the left or right it is. Or.... can you?

Sure, just like horizontal, just on the outside plane. It's harder to measure on bends less than 90 though.

I'm not a fan of tube bending, therefore probably not the best spokesperson. I do it, but I don't like it, plus I'm not a fan of a main hoop. I try my best to design my personal projects for each tube to have no more than one bend per piece. Simpler and stronger. I'd rather notch than bend...[emoji6].

Sent from my SM-G925R4 using Tapatalk

- Joined

- Feb 10, 2008

- Location

- Kings Mountain

[QUOTE

="mcutler, post: 1589841, member: 12432"]No it's not vertical on mine. I set it up with a piece of 1.75" dom, at zero degrees start of bend with the tube set parallel to the ground, so that I would always have a true angle reading on the tubing on the bent end.

="mcutler, post: 1589841, member: 12432"]No it's not vertical on mine. I set it up with a piece of 1.75" dom, at zero degrees start of bend with the tube set parallel to the ground, so that I would always have a true angle reading on the tubing on the bent end.

This will not work for every die or size, imho, at least it didn't on mine. So, I used the most popular die. I just have to remember to add or subtract when I change to the other size dies.... especially if I forget to adjust my degree pointer on the degree wheel.... but I usually just watch my digital angle finder.

-tip: when I'm running the die around to zero bend to seat the tube in the die, I crack the valve on the air cylinder enough to only seat the die, not start the bend... this lets me know I'm at zero.

Sent from my SM-G925R4 using Tapatalk[/QUOTE]

Quit yer bragging loser. And redo the junkass fuse block mount in your trap!

="mcutler, post: 1589841, member: 12432"]No it's not vertical on mine. I set it up with a piece of 1.75" dom, at zero degrees start of bend with the tube set parallel to the ground, so that I would always have a true angle reading on the tubing on the bent end.

="mcutler, post: 1589841, member: 12432"]No it's not vertical on mine. I set it up with a piece of 1.75" dom, at zero degrees start of bend with the tube set parallel to the ground, so that I would always have a true angle reading on the tubing on the bent end.This will not work for every die or size, imho, at least it didn't on mine. So, I used the most popular die. I just have to remember to add or subtract when I change to the other size dies.... especially if I forget to adjust my degree pointer on the degree wheel.... but I usually just watch my digital angle finder.

-tip: when I'm running the die around to zero bend to seat the tube in the die, I crack the valve on the air cylinder enough to only seat the die, not start the bend... this lets me know I'm at zero.

Sent from my SM-G925R4 using Tapatalk[/QUOTE]

Quit yer bragging loser. And redo the junkass fuse block mount in your trap!

catfishblues

Well-Known Member

- Joined

- Jul 26, 2005

- Location

- Pfafftown, NC

It looks like I am going to just make a vertical bender out of my JD2

I don't want to reinvent anything so I'm just going to copy some ideas. I really like the press/bender combo. I'll be doing that. It looks like @mcutler has the swag tools hydro mount and @catfishblues has the base/bottom mount.

I stole this picture from the for sale section because it is at a good angle credit to mcconnell

It looks like in the above posted benders that the C angle is not vertical but I can't tell what angle it is. Any particular reason for this?

As far as A & B. Where should the hydro cylinder mount in relation to the two bolts? This is the part I don't want to guess at.

View attachment 261621

At the start of the bend, the tube on the infeed side is not 90° to the fixed arm of the bender. Honestly, I guessed at my angles, and it worked out pretty well. I'm not horizontal feeding into the bender, but I get my die seated against the tube (like @mcutler said,) and zero my digital gauge on the infeed tube. It's angle will not change as you bend. Once zeroed, I stick the gauge on the outfeed side and it reads exactly what I'm doing. If you mount the fixed arm perpendicular to the ground, there's a good chance the tail of the tube will be on the ground before you start your bend. As for the air over hydro setup, my whole thing was homebrewed in an afternoon in the shop. I didn't use any Swag parts. Didn't use any on my power conversion on my tube roller, either, although it may have been "inspired" by their setup!

@shawn, you can reference easily off the side of the die to account for tube twist. Honestly, though, in my limited experience, I haven't noticed any. Just shitty bends due to my own rushing and trying to eyeball things.

Last edited:

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

I assume your refering to the twist in the Pro Tools vid.........honestly I call b.s. on that phenomenom. I think that "might" occur when you dies are off center from each other or the machining is not parallel for the path of the tube. I got a buddy who owns that specific bender. Its like a JD square knock off. Nothing is as near the quality and precision. It also binds badly and can be a real pain to unlock and remove the tooling.So... @mcutler @catfishblues

When they're mounted vertically, how do you account for twist? If the bender is mounted horizontally, you can true the angle finder and measure the twist in the tube. If the die is mounted vertically, you can't measure how far to the left or right it is. Or.... can you?