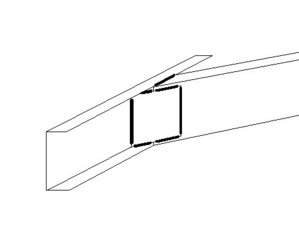

I will cope them first chance I get.

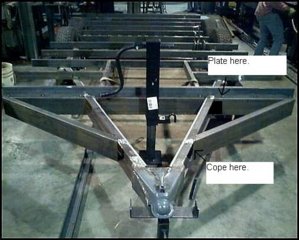

It was mentioned that the extra bracing will be a problem when turning the trailer. What are your thoughts on this?

Thanks

Will

Bracing is no problem the way I see it...

OK

Want to say something, Anyone- spend time to learn what is going on here. Yes it may not be the best but he is working with what he has. He has made a few changes and yes it may not be the same if he had better plans to start with, this is a class, he is in class to learn, its all part of it.

Will,-- I think you are doing fine and it will be a good trailer and a safe one when you get done. Yes if I would be building it, I may have done things different and along with Rock or others.

We have built them and know what we like.

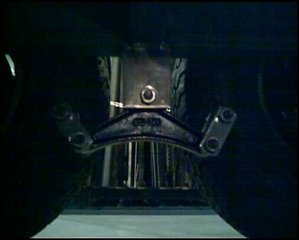

Yours will be fine. Yes you need to do something with the braces the way they weld to the front, it could be plated like what we do on bridges or cope them as long as it is tied good it will be fine.

I don't think you will have any problem turning, No its not a GN but it will turn as much as you need or should.

Look at other trailers and you will find the tongue will go from the outside of the trailer to the ball mount or within 6" of the outside. If you draw a line from the outside of the bed on the trailer to the ball you will see that the braces will not cause a problem and will be better then other Factory trailers for turning. Look at Prolines website..... Plus if you use a WD hitch then that is the limits of turning not your bumper.

Yes you need to look at a few things and fix a few but you are doing fine.

I really cant see why the people that just want to pick at you and make problems have not caught that your welding it is just tacked and say something like I dont think those welds are not going to hold crap.....

Jon