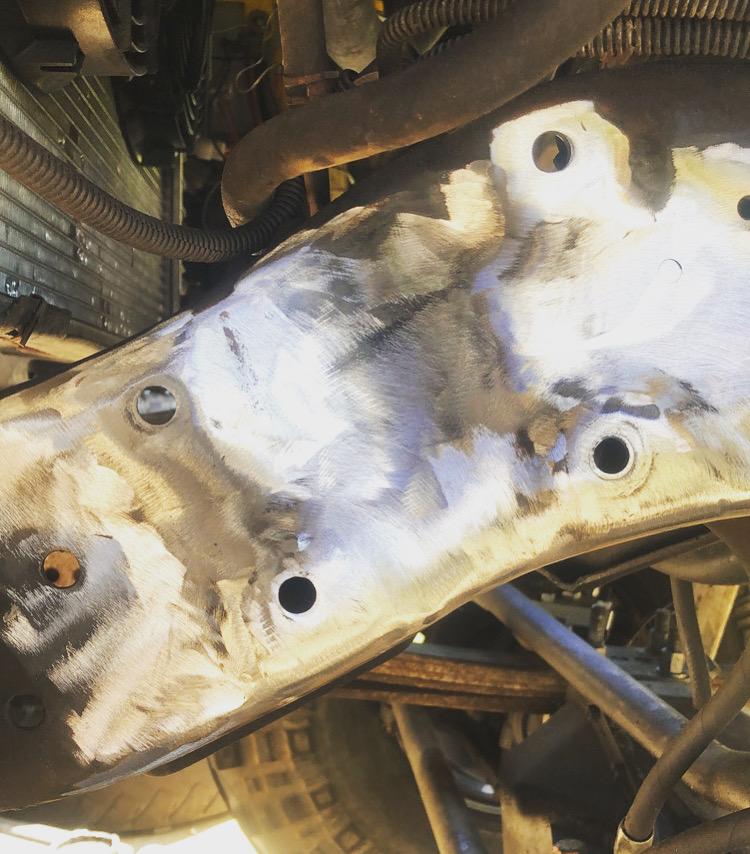

Back to a strong maybe for attending the thing, got to order some front frame plates before I can finish doing the front hoops. Been waiting on dude to release them, this is the ones I’ll be using.

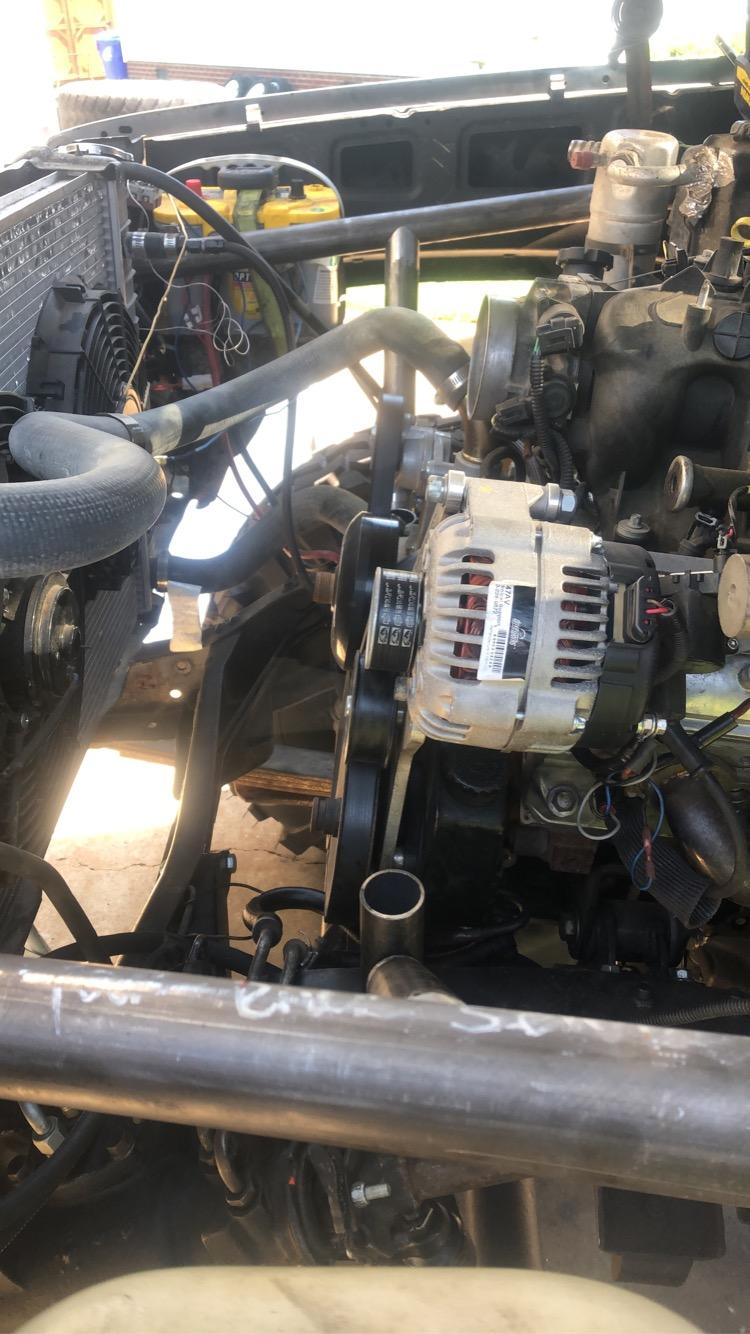

But shifter is back to shifting, got a whole laundry list of stuff I’m starting this morning. Me double checking fuel pump wiring to make sure it was the pump the other week, I didn’t put the PCM back. So during me bullshitting the other day after fixing the shifter, PCM fell over and yanked a terminal out of for fuel pump, so I’ll be fixing that this morning, along figuring out a better way to mount the PCM. Gotta take the dash off because I need to replace the speedo cable. I broke because the was too close to the exhaust. Took longer than expected. Also trying a 3rd oil pressure sending unit hoping this works so all my gauges will be working and it won’t be as white trash. Been looking at new dash pads because mine is a ratty piece of shit, but my god is they are proud of the nice ones. That’s gonna have to wait.

Also got an upper radiator hose that wasn’t secure and got into a tensioner and needs to be replaced before the trip. Wasn’t leaking been keeping hose and coolant in the truck with the tools to change it if it left me stranded. But I don’t need to keep playing with fire. I need to pick up another driverside hub seal, this ones leaking again. I swear oreilly’s seals ain’t with a shit, I’m better off ordering from ECGS.

I’ve got the parking brake hardware and the factory drum parking brake cables off a set of 1 tons I picked up years ago. I’m gonna attempt to connect them to the factory pedal. Figure it would be pretty cool and keep stuff out of the shifter area. The t-case shifters take up a lot of room.

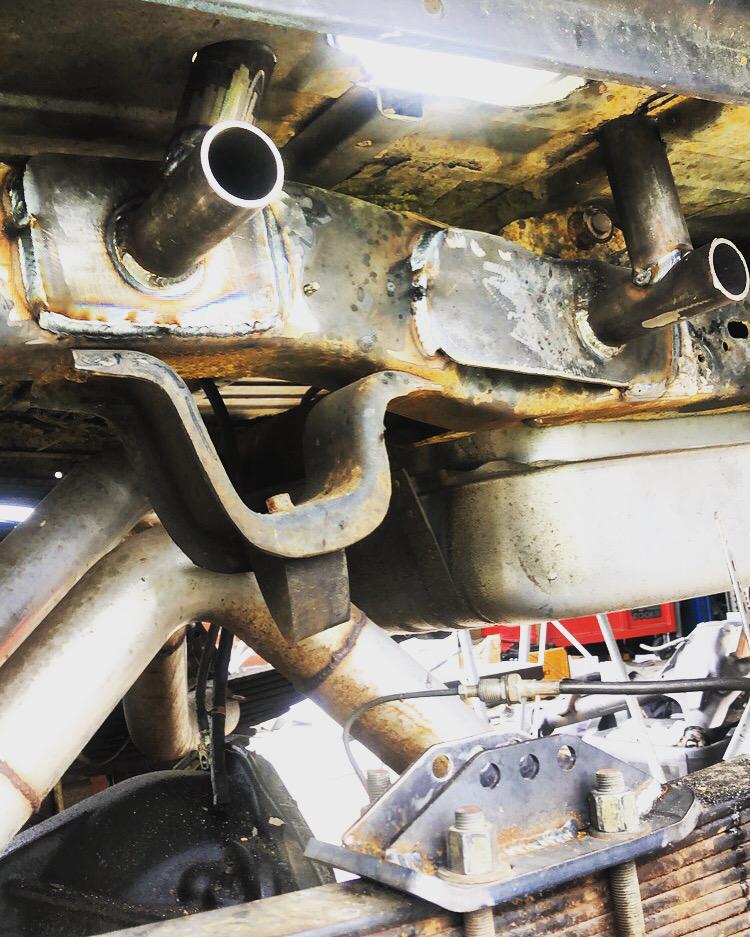

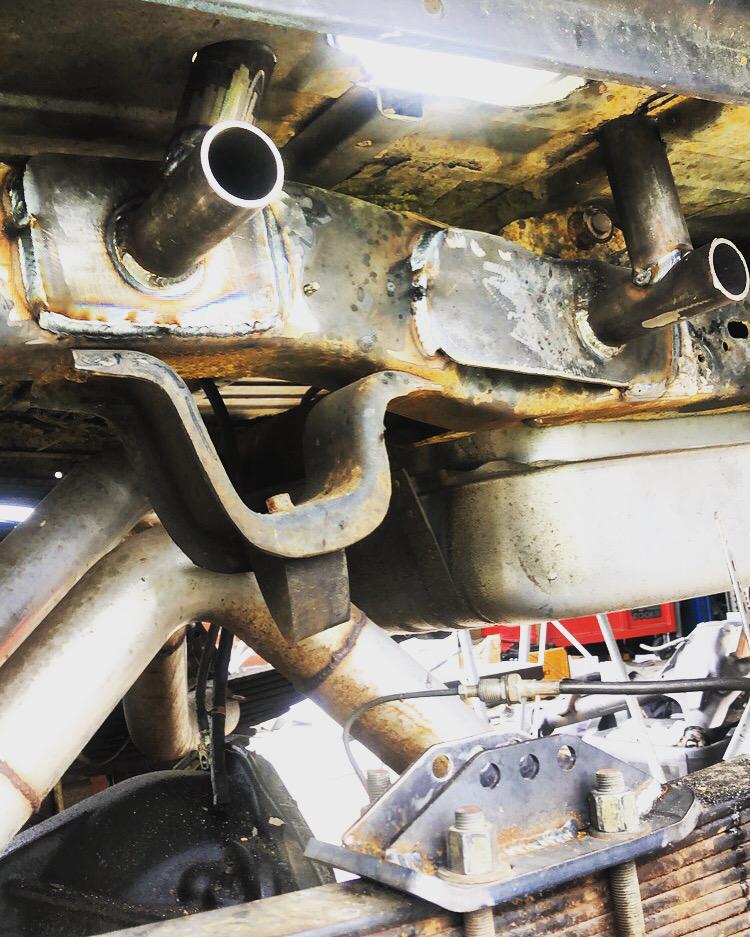

In order for me to raise the tcase anymore I’ve got to cut the floor. Which in cool with. I’ve got some sheet metal to go back over it. But this is also so I can just finally have a decent crossmember. I’ve got enough 1.75 DOM I think I can come up with something that should strengthen it up and help strength the chassis as well. I really want to box the frame rails, but I don’t really see that happening in time for the 25-26 weekend. Front hoops and inner fenders are my main focus. Really need to figure out a different routing of my Y pipe because that is limiting me to 4” of uptravel on the passenger side, I can redo that later And the way I’m doing the shock mounts I think I’ll be able to cut it out and just move the upper mount. Still need to pick up tubing flanges or decided on the inner locking ones.

I’ve wrapped these springs a little, but I think I’ll have enough adjustment in them that when or if I do put new springs in there, I’ll be able to make the traction bars work.

This is the type I’m gonna try out. Hopefully works, lol.