Mac5005

Well-Known Member

- Joined

- Oct 19, 2005

- Location

- Rocky Mount

Got a project coming up that is rear engine.

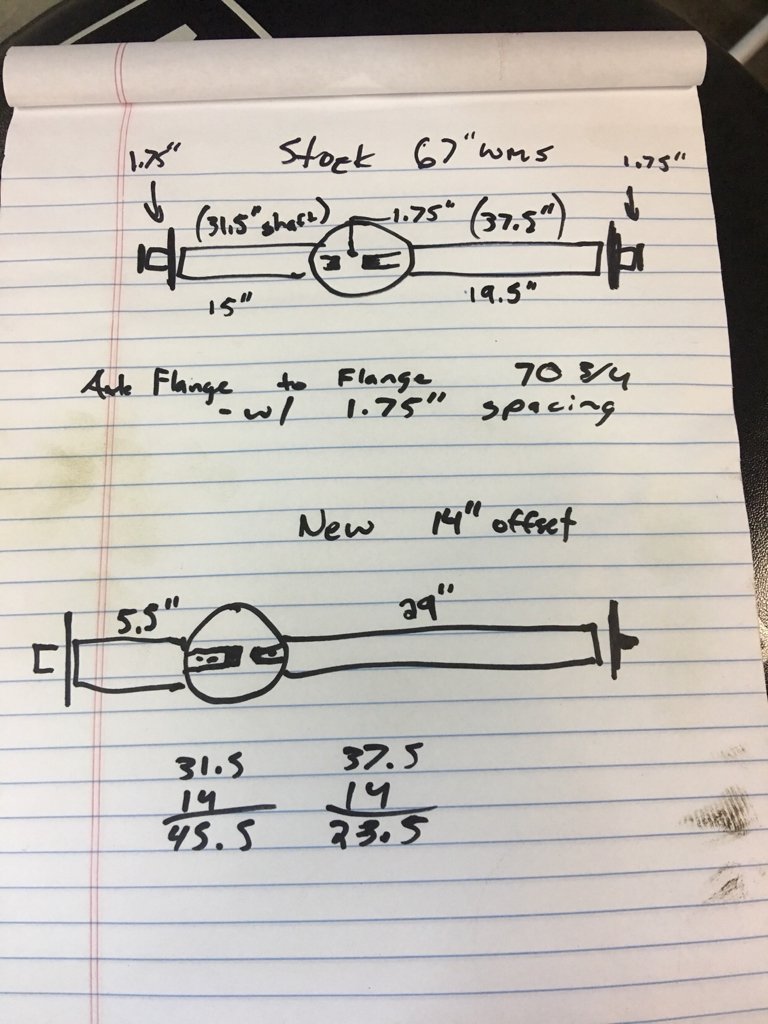

Plan is to flip and offset the 14b for rear engine.

The axle needs to be offset as far as possible to driver side to clear the engine. This will somewhat convert it to high pinion.

I’m not concerned about oiling as this will be for low speed Offroad use only. No highway use.

Thinking I may have to put a seal in the long side tube to keep the oil from just filling up pass side tube when off-camber and articulating.

Just going to do a raised fill plug on cover.

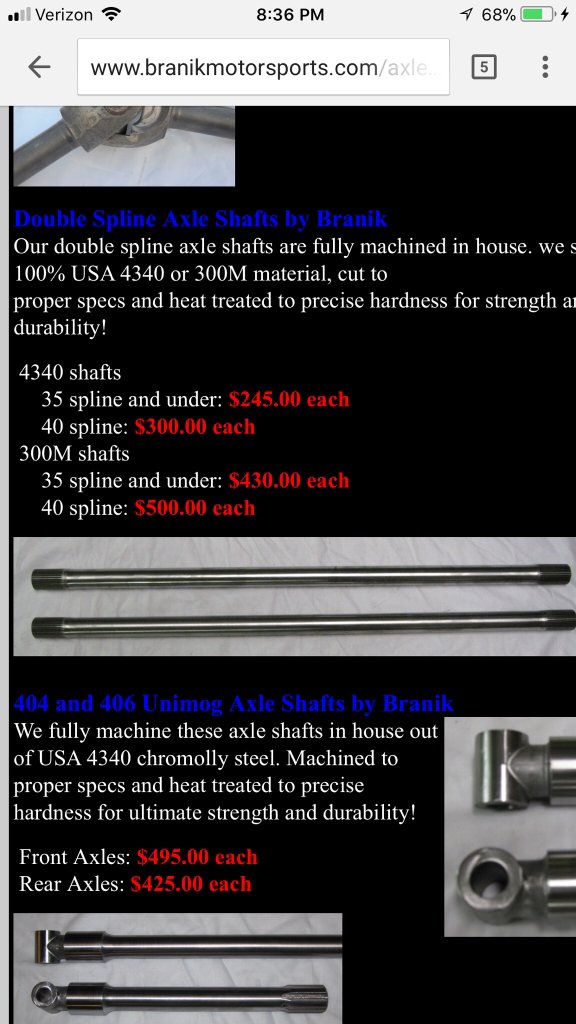

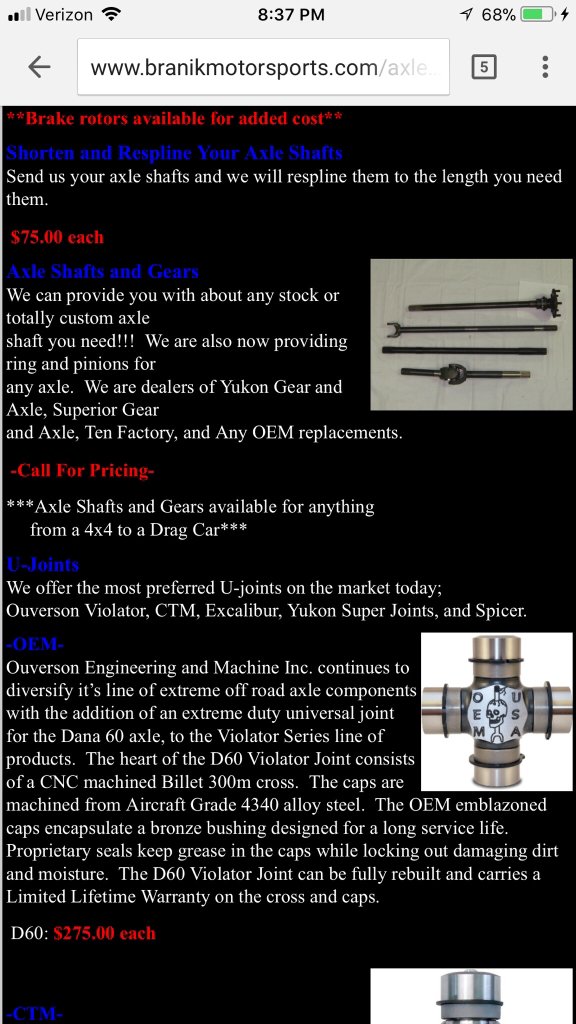

Current plan is to have branik shorten and respline two stock shafts for the short side because it’s cheaper.

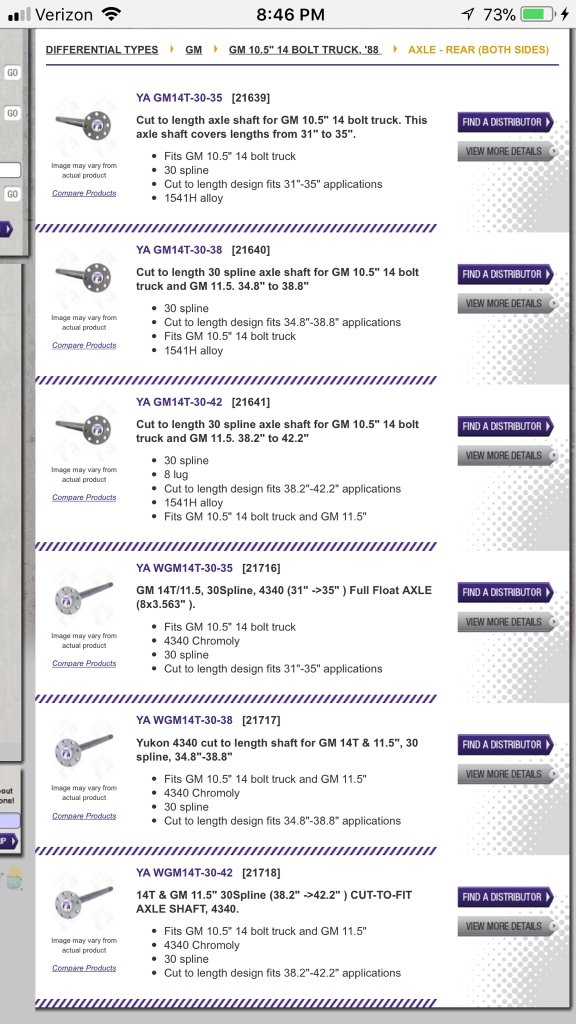

As far as the long side, what mfrs are out there for a custom Long side shaft?

What limits are there for shaft length? Is it necessary to convert to double splined shaft or does anyone make longer than stock shafts with a flange. Double splined would require a different spline count and pressure angle that inner splines.

Hoping to keep with 14bolt diff/carrier options, but backup plan is welding d60/70 side gears into an open 14b diff and running double splined 35 spline stuff.

Just the beginning of this, and going to have to work thru all the issues before completion.

Searched pirate and very little tech and pictures remain, so hoped to have this thread for info/tech and somewhere to put all the info as I work through it.

Going to do this without retubing if all possible.

Going to see if I can cut the spindles out of the oem tubes and shorten the one side, and then have to figure out a splice/overlap with tube for the long side. If that seems to be an issue, I will cut and shorten/lengthen the tubes using an inner tube to make the splice. It will get a full truss that ties into the pinion and cover.

The plan for the front is to grind the welds off the inner C’s on the KP dana 61, flip it also, and reweld the c’s back on, that will also allow me to set the caster and pinion angle.

Yes I know about driving on the wrong side and oiling concerns....going to avoid that all together for now.

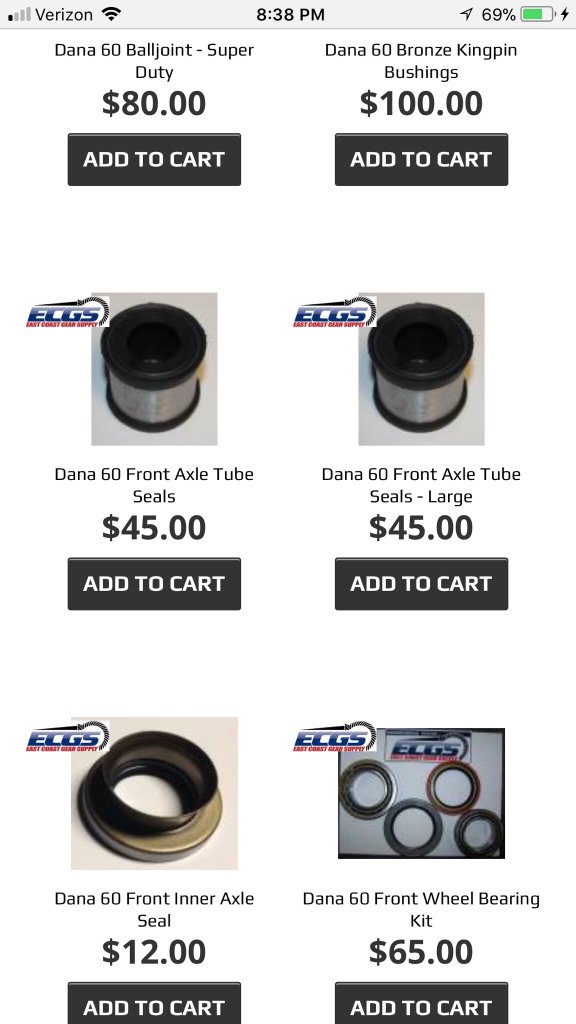

I plan to run off the shelf dodge/Chevy 4340 ecgs front shafts, unless i decide to narrow the long side inner just to keep overall width down.

I have $200 in the d61/14b pair, so I’m not too deep into it and can afford to hack on them without worry.

Plan is to flip and offset the 14b for rear engine.

The axle needs to be offset as far as possible to driver side to clear the engine. This will somewhat convert it to high pinion.

I’m not concerned about oiling as this will be for low speed Offroad use only. No highway use.

Thinking I may have to put a seal in the long side tube to keep the oil from just filling up pass side tube when off-camber and articulating.

Just going to do a raised fill plug on cover.

Current plan is to have branik shorten and respline two stock shafts for the short side because it’s cheaper.

As far as the long side, what mfrs are out there for a custom Long side shaft?

What limits are there for shaft length? Is it necessary to convert to double splined shaft or does anyone make longer than stock shafts with a flange. Double splined would require a different spline count and pressure angle that inner splines.

Hoping to keep with 14bolt diff/carrier options, but backup plan is welding d60/70 side gears into an open 14b diff and running double splined 35 spline stuff.

Just the beginning of this, and going to have to work thru all the issues before completion.

Searched pirate and very little tech and pictures remain, so hoped to have this thread for info/tech and somewhere to put all the info as I work through it.

Going to do this without retubing if all possible.

Going to see if I can cut the spindles out of the oem tubes and shorten the one side, and then have to figure out a splice/overlap with tube for the long side. If that seems to be an issue, I will cut and shorten/lengthen the tubes using an inner tube to make the splice. It will get a full truss that ties into the pinion and cover.

The plan for the front is to grind the welds off the inner C’s on the KP dana 61, flip it also, and reweld the c’s back on, that will also allow me to set the caster and pinion angle.

Yes I know about driving on the wrong side and oiling concerns....going to avoid that all together for now.

I plan to run off the shelf dodge/Chevy 4340 ecgs front shafts, unless i decide to narrow the long side inner just to keep overall width down.

I have $200 in the d61/14b pair, so I’m not too deep into it and can afford to hack on them without worry.