ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

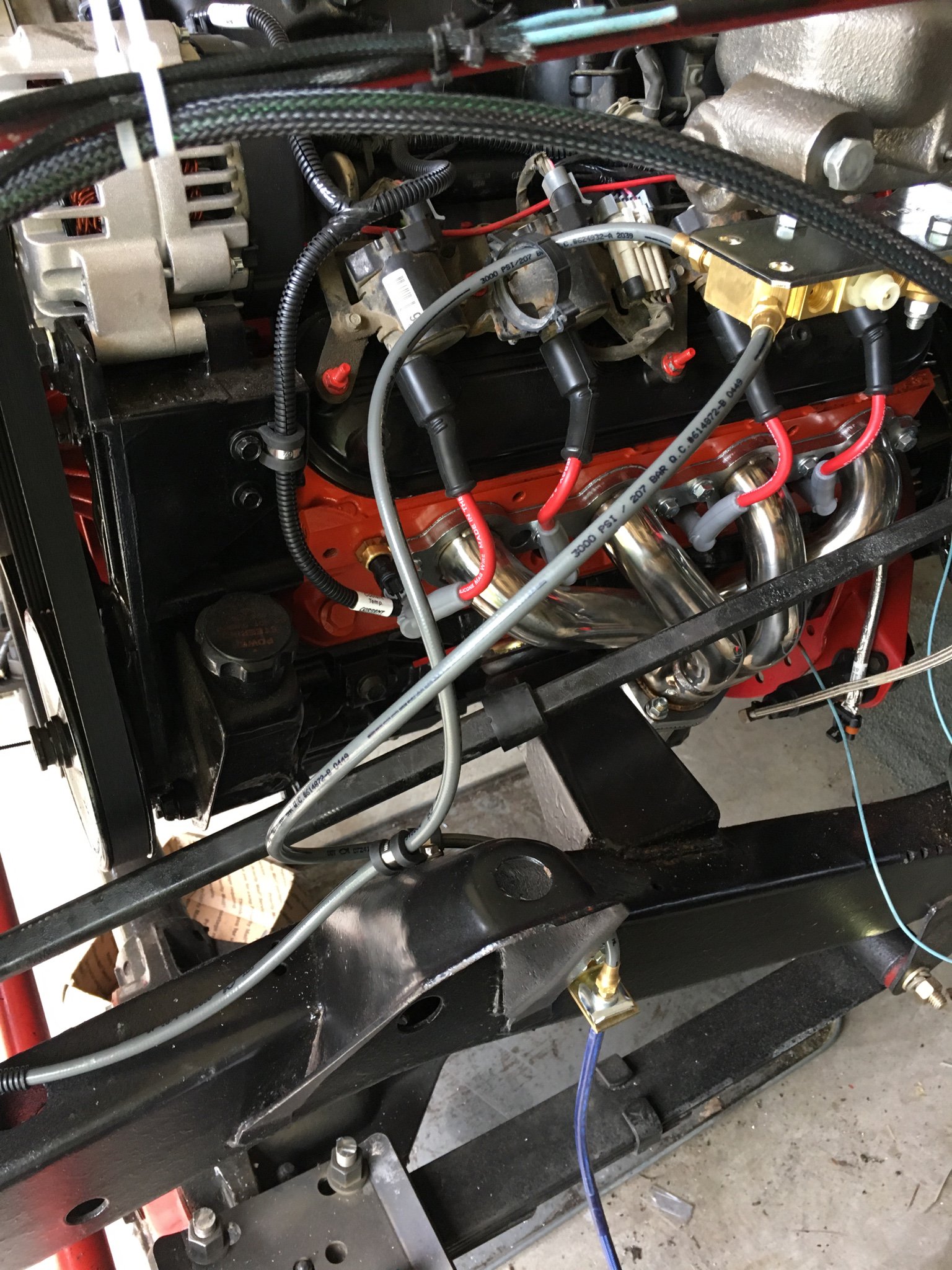

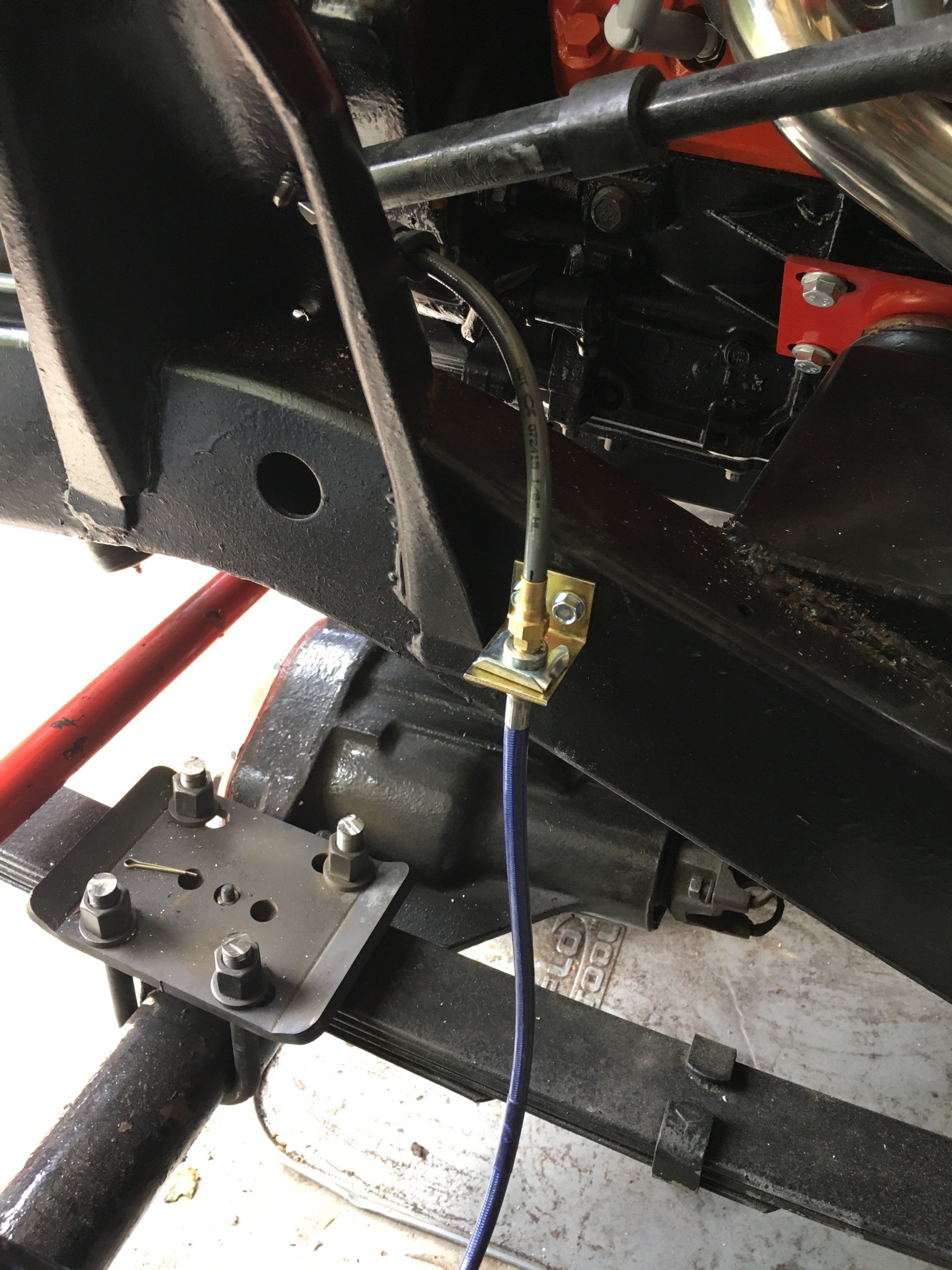

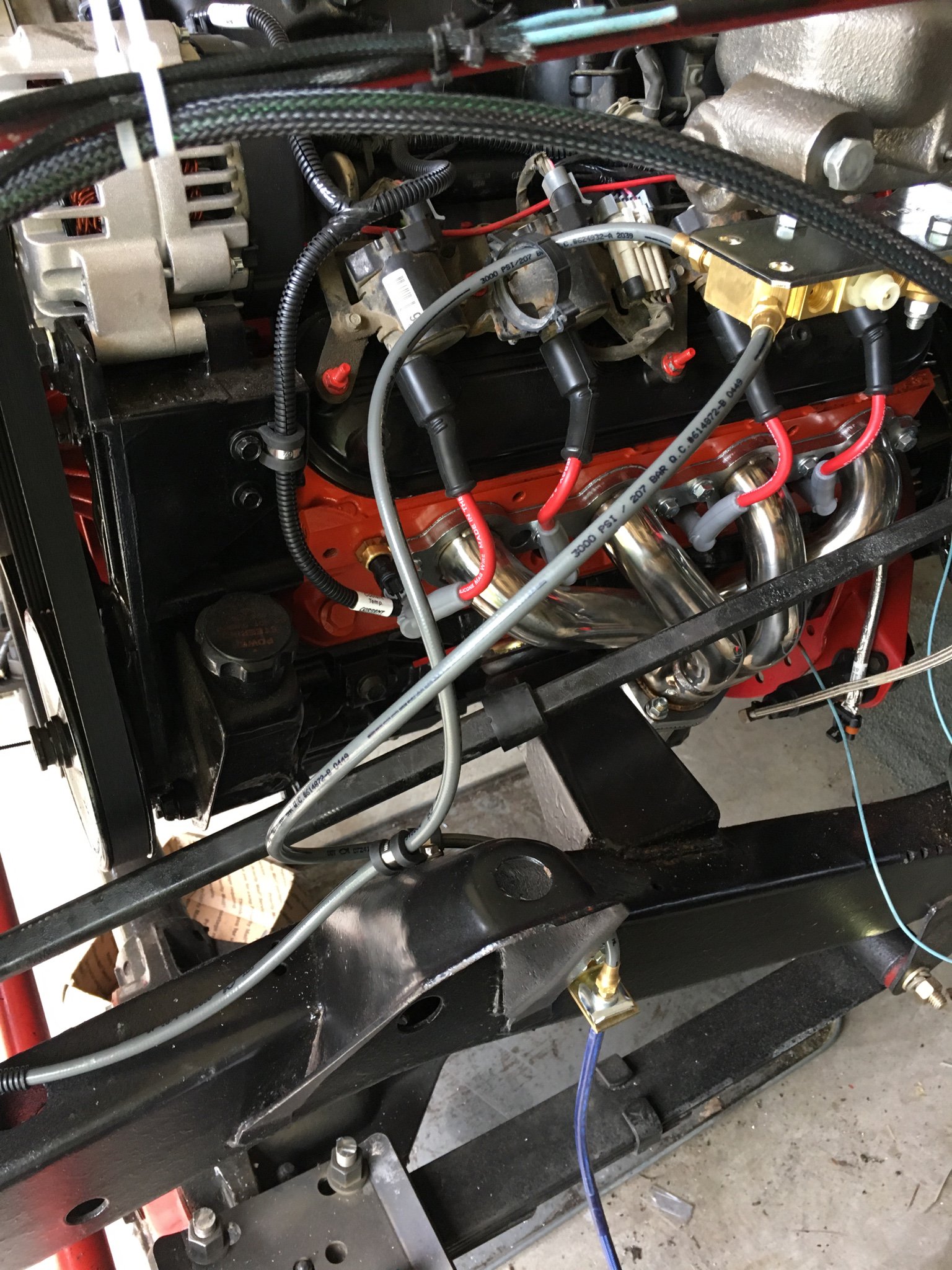

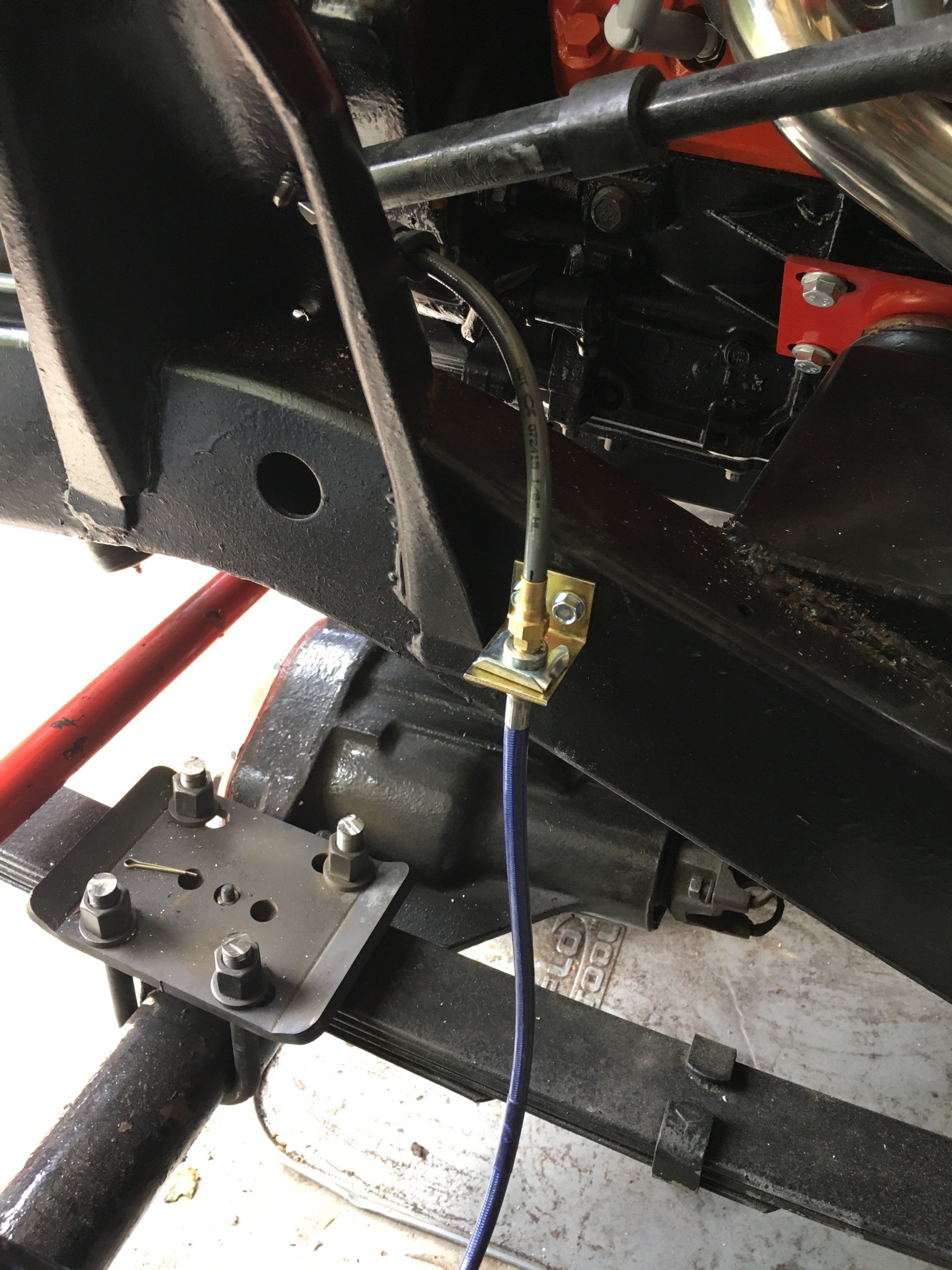

Ugh low motivation today. Got front brake lines hooked up. Had clearance issues with the steering shaft and the rad so temp secured it about an inch higher and when I go put the hoses on I'll finalize its placement.

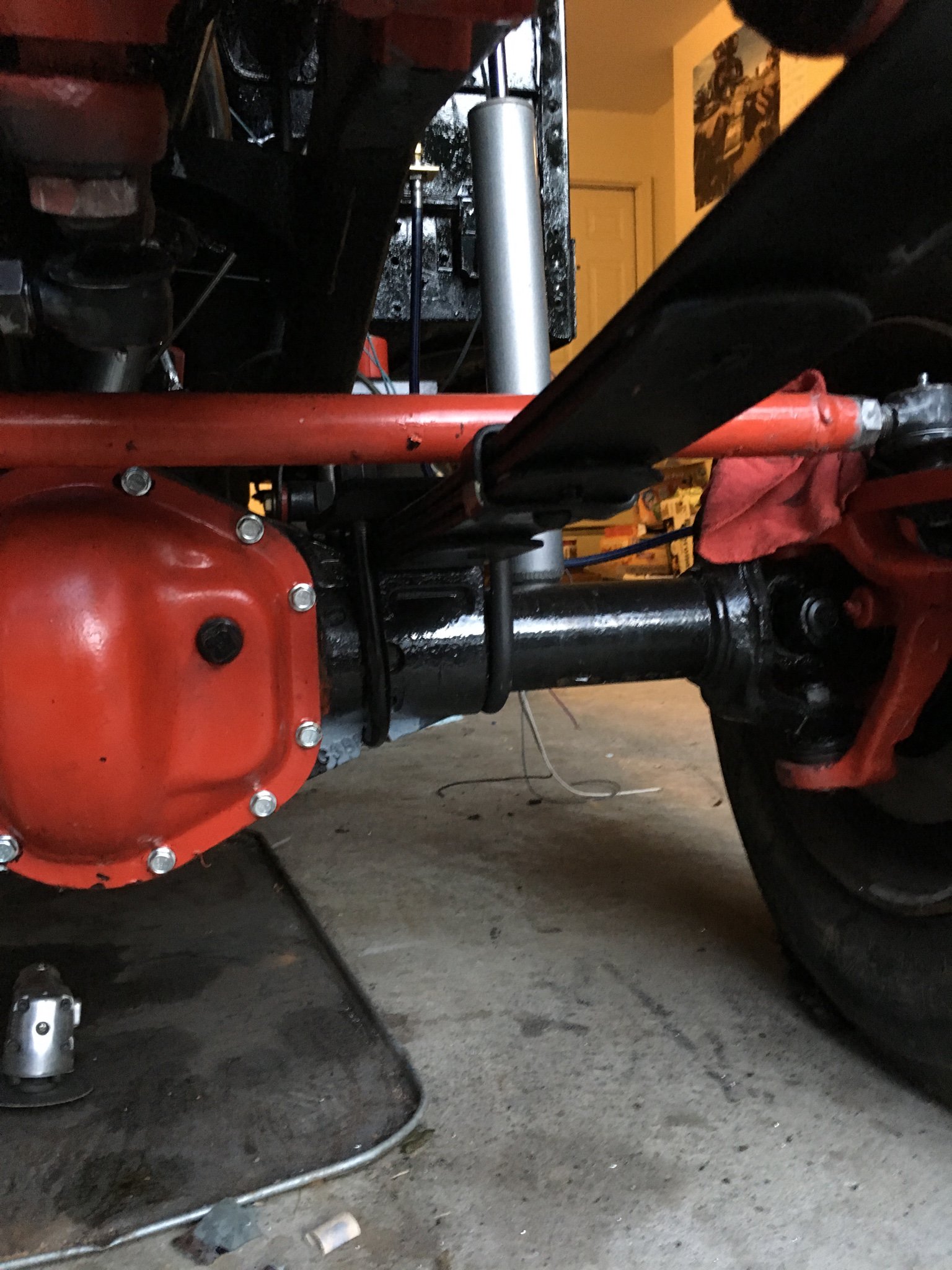

Cut the ubolts.

I guess the low motivation stems from going out there this morning and spending 4 hours fudging with the steering shaft. It's rusted in place and doesn't collapse anymore. So the high hopes of getting everything done this weekend but driveshafts isn't looking good.

Speedbump at it again lmao

Ok done whining. Going back out there and see what we can get done!

Cut the ubolts.

I guess the low motivation stems from going out there this morning and spending 4 hours fudging with the steering shaft. It's rusted in place and doesn't collapse anymore. So the high hopes of getting everything done this weekend but driveshafts isn't looking good.

Speedbump at it again lmao

Ok done whining. Going back out there and see what we can get done!