Besides setting up the dana 300 gears this might be the most challenging hurdle to get over. Mounting the cable shifters without cutting a massive hole in the tran tunnel, however looking back it may not have been such a bad idea

I ordered the JD fab shifters without doing a super detailed measurement for fit type of deal and I didnt realize how small 48" cables are when you make a big "U" with them. And gosh darn are they stiff as balls.

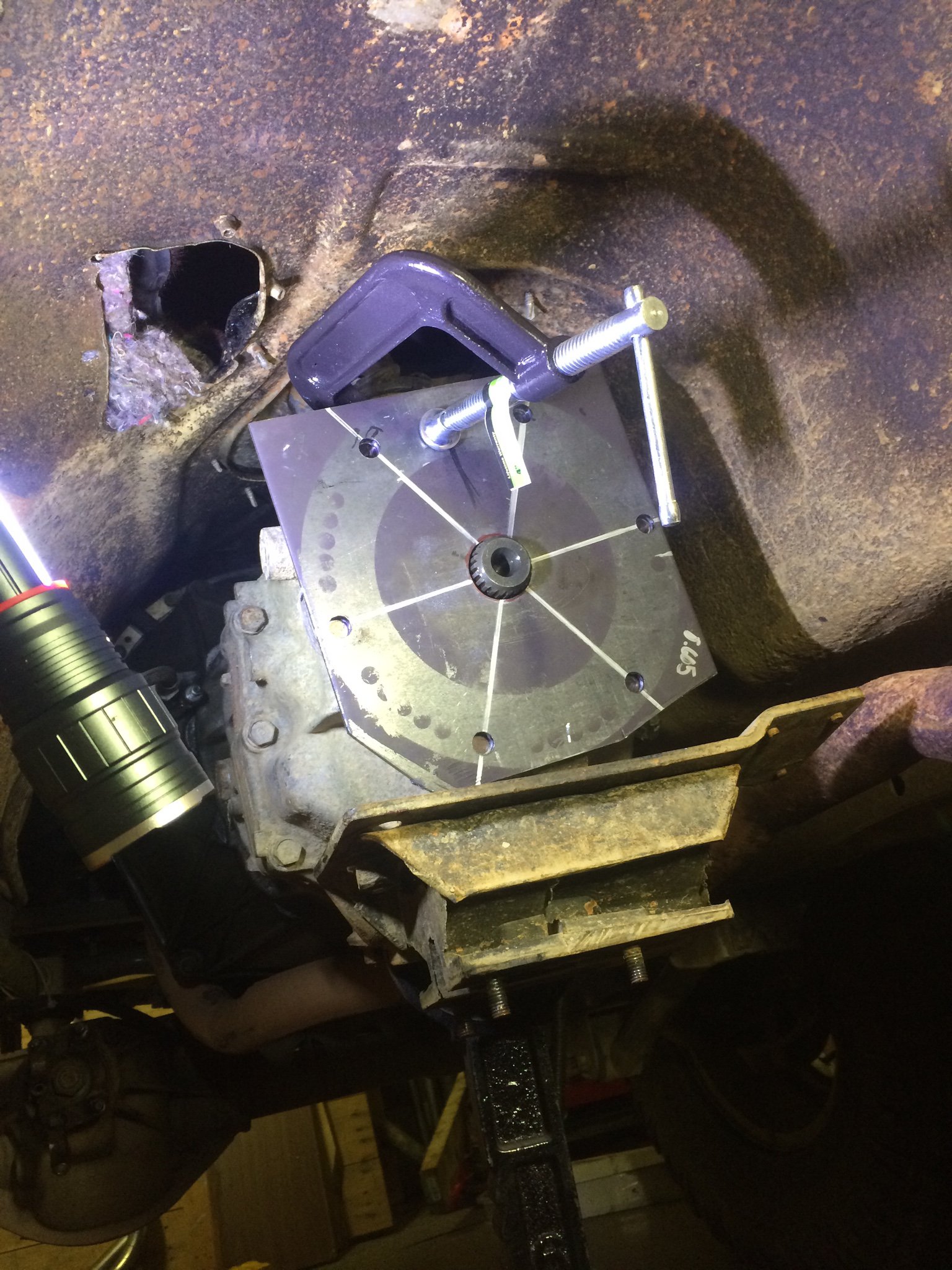

Anywho I present hole in with shifter plate

Took me a lot of thinking to get to this point

Now the shifters are basically in the same hole the original shifter was in except it is longer. Move the shifters any more toward the dash and length of cable gets close to no room for error. Some bracket fabbing and hardware get me complete and permanently mounted. I will be adjusting to how tall they are and the loss of leg room for the right leg

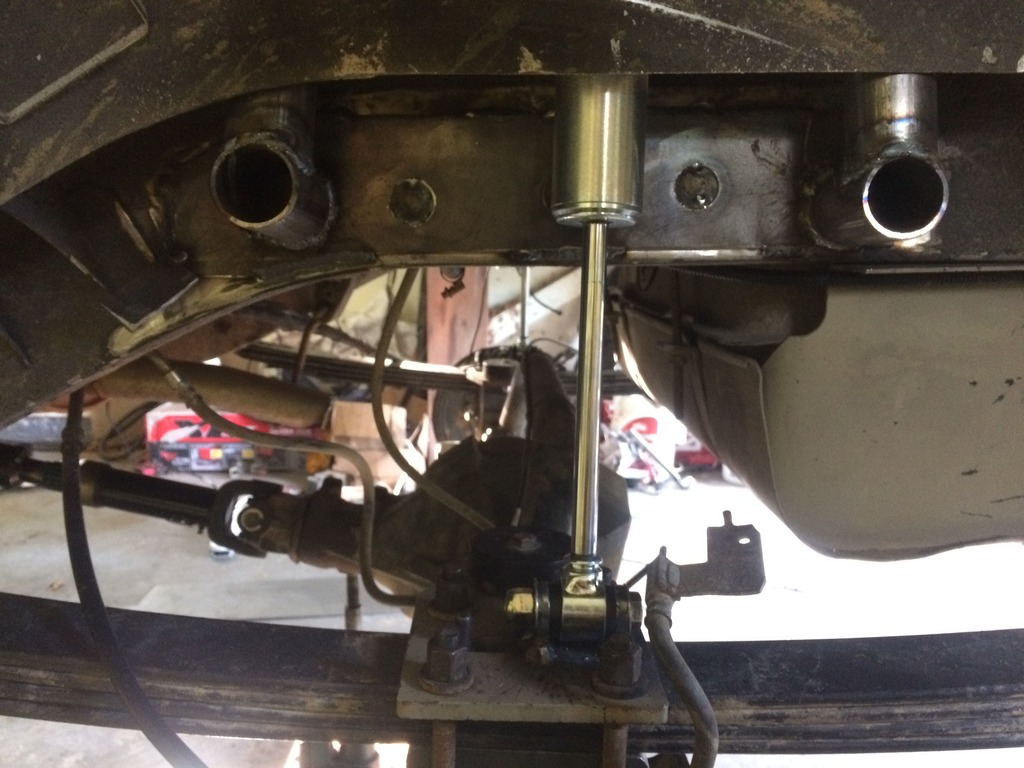

Underneath it packages nicely but the cables are at their limit for being in such a small area. I am thinking of banging the floor board open where the tunnel ends. This is the tightest clearance as the bend of the cables are getting interfered with.

So I promised not to laugh and see just how long it took for the case to start leaking gear oil. After about 10 minutes I saw the first drip, but thankfully it came from the sight tube fitting. The original sight tube I picked was ordered from mcmaster and was fade resistant but extremely stiff, basically plastic. Well the fitting didn't like that and was dripping in no time. So I swapped it back out for the cheapo tube I had bought from the hardware store and no more "immediate" drips

Closer up view of a small gap seperating the tcase from the shifters. Maybe <1"

I test drove it in my long driveway (to afraid to take it down the road at the moment)

The reduction is awesome. It barely even moves in reverse. Shifters are very tight. The rear axle shifter has less resistance than the front axle, which concerns me about popping out of gear but we never know until it gets out onto the trail. Let's hope I don't have to tear into this for any reason. Lowest forward reduction is 3.83 x 4.56 x 4.0 = 69.9:1 It's no yota but it should perform well!

The reduction is awesome. It barely even moves in reverse. Shifters are very tight. The rear axle shifter has less resistance than the front axle, which concerns me about popping out of gear but we never know until it gets out onto the trail. Let's hope I don't have to tear into this for any reason. Lowest forward reduction is 3.83 x 4.56 x 4.0 = 69.9:1 It's no yota but it should perform well!

The reduction is awesome. It barely even moves in reverse. Shifters are very tight. The rear axle shifter has less resistance than the front axle, which concerns me about popping out of gear but we never know until it gets out onto the trail. Let's hope I don't have to tear into this for any reason. Lowest forward reduction is 3.83 x 4.56 x 4.0 = 69.9:1 It's no yota but it should perform well! This morning I enlisted the GoPro to be my eyes and check in on the axle wrap symptom I created by pushing the axle back with a glorified block. Even though the leaf springs are pretty stiff coming from a 3/4 ton van they are wrapping enough just by accelerating hard on the pavement to give me the fritz.

This morning I enlisted the GoPro to be my eyes and check in on the axle wrap symptom I created by pushing the axle back with a glorified block. Even though the leaf springs are pretty stiff coming from a 3/4 ton van they are wrapping enough just by accelerating hard on the pavement to give me the fritz.